GENERAL AVIATION Revitalising UK light aircraft manufacturing

Inspiration nation

TIM ROBINSON FRAeS reports on a bold, multifaceted project to kick-start a renaissance in British light aircraft design, manufacturing and training, as well as inspire a new generation of aerospace professionals.

The UK-designed Game Bird GB-1 aerobatic aircraft is now being manufactured in the US. GameBird Aviation

The UK-designed Game Bird GB-1 aerobatic aircraft is now being manufactured in the US. GameBird Aviation

Pre-pandemic, regular statistics trumpeted that the UK is the second (or third, vying with France) biggest aerospace industry in the world. While it might not build entire airliners, it still maintains a dominant position in wings, engines and landing gear while its military aviation sector provides the bulk of UK defence export revenue. Meanwhile, the UK’s space sector continues to expand, from small satellites, to Mars Rovers and now even launchers.

Yet one sector continues to be underappreciated and underinvested – despite the UK’s aeronautical heritage, engineering prowess and world-class reputation in aerospace – that of general aviation. Where for example, is the UK’s equivalent to Cirrus Aircraft? Or Diamond or Jabiru? Even Slovenia, a country of 2.1m, has Pipistrel – which is now leading the field in pioneering electric aircraft and which was recently acquired by the US giant, Textron.

As Tim Cooper noted in the April 2021 issue of Pilot magazine, outside of a cottage industry of microlight and non-certified light aircraft and excluding the larger Britten-Norman Islander: “The fact remains that there is not a single British designed and built, light aeroplane certified to current standards available for the patriotic private pilot, or indeed for foreign pilots who would like to buy a machine from a national lineage that stretches back to the early days of powered flight.”

An ideal breeding ground?

With low entry requirements, scope for innovation and an affordable way into aviation, GA in the UK should be an ideal breeding ground for agile startups – but so far this vision has arguably failed to materialise – despite the arrival of e-Conditions to stimulate innovation, a Transport Secretary who is a keen private pilot and the GA APPG being the largest all-Parliamentary interest group. The UK government’s stated aim to ‘level-up’ neglected regions through stimulating investment also should align perfectly with GA, given the small airfields that could benefit local economies and communities.

Inspired’s first aircraft will be a Sling TSi kitplane, which will be used to develop its model of a distributed light aircraft manufacturing network. Nick West/Inspired Aviation

Inspired’s first aircraft will be a Sling TSi kitplane, which will be used to develop its model of a distributed light aircraft manufacturing network. Nick West/Inspired Aviation

For its part, the RAeS has also been working hard to inspire young minds through its hands-on Schools Build-a-Plane initiative with Boeing and the new Falcon 2 initiative – aiming to use GA as the entry point and hook into wider aerospace careers.

Meanwhile, the introduction of new EASA CS-23 rules for GA in 2017 has unleashed a wave of innovation and creativity on the continent with start-ups, like France’s Elixir and Aura, as well as Slovenia’s Pipistrel. Given these drivers then, where is the UK’s equivalent to Diamond or Cirrus?

Enter Inspired Aviation

This paradox of Britain’s missing GA sector was one of the drivers for a new company formed in 2021, Inspired Aviation, founded by ex-Air League CEO, Nick West who notes that Britain has been “punching below its weight” in GA, despite its impressive capabilities in almost every other sector of aviation and aerospace.

West argues that despite the UK’s high-tech aerospace sector and large primes, there is now a lack of clean-sheet aircraft programmes for young people to cut their teeth on, gain experience and develop innovation. (Indeed, as well as military requirements and export potential, the need for a new combat aircraft programme to pass on critical knowledge and skills, was one of the drivers behind the Team Tempest sixth-generation fighter programme.)

THERE IS NOT A SINGLE BRITISH DESIGNED AND BUILT, LIGHT AEROPLANE CERTIFIED TO CURRENT STANDARDS AVAILABLE

Tim Cooper Pilot magazine

Inspired’s ambitious goal is a wide-ranging transformation of the UK’s GA sector, by lowering the barriers to entry and ‘‘democratising’ light aviation. Through a network of design centres and ‘shadow factories’, building aircraft and parts across the UK, it plans to develop a family of modular, affordable light sport aircraft that can stimulate a grassroots revolution in light aviation and, crucially, excite and nurture future talent. It would also act as a showcase and incubator for international students to cut their teeth in design, manufacturing and flight training.

Says West: “We see an opportunity for connecting the manufacturing activities, to design and development, and working in a very collaborative way to reduce the cost of aircraft development, and reduce the cost of flying training ultimately, and therefore increase the access to it.”

Inspired sees this as not only making for an economic and societal revolution in light aviation that will benefit aerospace itself, but also providing a training ground for engineers that may go and work in adjacent industries or other sectors – bringing ‘air-mindness’ back to the masses.

France’s Elixir Aircraft has benefited from a change in EASA regulations covering light aircraft. Elixir Aircraft

France’s Elixir Aircraft has benefited from a change in EASA regulations covering light aircraft. Elixir Aircraft

The looming pilot shortage

This is not just an issue that is confined to the UK and its GA sector. Despite the ravages of the Covid-19 pandemic, the aviation industry is already warning of a growing future pilot and engineer shortage on a global scale.

While it can boast the ‘cool factor’ of reusable rockets, hypersonic aircraft and eVTOLs, aerospace must now compete with app developers, IT start-ups and emerging careers to attract the best and the brightest.

Moreover, the sector has seemingly erected higher barriers to entry, with the average cost of training to become a commercial pilot being around £120,000 and even private or recreational flying being out of the budget of many who would love to fly, if only it were more affordable, when a PPL could set you back around £10,000.

It, thus, could be argued that scholarships and bursaries towards pilot training, though extremely valuable and laudable by themselves, are only really treating the symptoms, not the underlying cause that private aviation has gradually become unaffordable. What then, if the cost could be radically slashed?

Meanwhile, these underused local airfields are also under threat, from nearby residents complaining about the noise, or property developers eyeing prime real estate to make a quick buck.

Finally, the track record of UK attempts to crack the light aircraft sector with innovative designs has arguably not been a success – from the Planet Satellite, to the Edgley Optica, Farnborough F1, Trago Mills SAH-1 and ARV Super 2 all ending in very small numbers built at best. The latest attempt, the Game Bird 1 aerobatic aircraft, like the Farnborough F1/ Kestrel K-350, has now migrated to be built in the US.

The time is right

However, West believes that in the past few years, a number of converging technologies and trends have come together to make a revolution in UK GA feasible. “Technologically, there are things that can be done in GA now, in terms of manufacturing, that were different to several years ago.

IT’S ALL ABOUT THE HUMAN ENDEAVOUR, INNOVATION, THE PIONEERING SPIRIT AND ACCEPTING THE FACT THAT WE HAVE TO DO SOMETHING DIFFERENT IF WE WANT THE INDUSTRY IN THE UK TO THRIVE

Nick West CEO Inspired Aviation

If you look at the High-Value Manufacturing Catapults network, you look at the rapid prototyping capabilities that are being developed now, and then you look at the material science, you look at computing, you look at 3D printing technologies, if you look at autonomous and conspicuity systems, there are so many things that are being worked on now that give the ability to leverage, or utilise these advanced capabilities into next-generation platforms.”

Indeed, the development of systems like Garmin’s Emergency Autoland shows how, in some areas, GA may even be ahead of other sectors. All these, says West, means: “If you can bring the capability up, and drive the cost down at the same time, that is your Holy Grail”.

With the right design combined with low acquisition and operating costs, yet advanced capabilities, West believes that a fresh British designed and built next-gen light aircraft could have the potential to address a worldwide GA market of 3,000 aircraft a year. Says West: “If we could capture a small percentage of that, obviously representing the UK, that would be tremendous.” He and his small team have also got their sights on the military trainer market, where there is a need for 500+ ab initio aircraft over the next decade. In particular, West sees that a net zero trainer from Inspired could well be a perfect fit for the RAF’s Project Telum, which aims to deliver a zero-carbon, certificated elementary trainer to meet the services’ goal of net zero by 2040 – “we’d obviously be delighted to bid for that, at the appropriate time.”

A previous British low-cost light aircraft, the e-Go was aimed at making aviation more accessible but was constrained by being a single-seat design. GeoCAS

A previous British low-cost light aircraft, the e-Go was aimed at making aviation more accessible but was constrained by being a single-seat design. GeoCAS

A two phase plan

Inspired is taking a stepped approach to realise its vision with the immediate priority to develop a ‘federated’ manufacturing network for light aircraft across the UK. Says West: “We want to create a manufacturing network that’s common tooling, common systems, common processes, so that when we’ve got to the point where we’ve developed our own aircraft, we can build those planes across our network”. To that end, it will first use an existing kitplane design to build up experience and processes before developing its own aircraft.

“What we’re trying to do is not front-load massive engineering cost into the organisation, because that’s honestly an area where people have come unstuck in the past”, says West. Inspired is set to order its first home-build aircraft, a four-seat South African-designed Sling TSi as this is being written, and is in discussions for second and third kits, which may not necessarily be of the same type. The build locations are also currently being kept under wraps.

A true next-gen light aircraft

Beyond this, Inspired’s plans is that Phase 2 will see the company develop a clean-sheet low-cost, yet highly capable family of two/four/six/eight-seat light aircraft for the global training and touring market, using the latest materials, technology and production processes with standard parts across the whole family to drive costs down.

Inspired’s modular family could spin out into rotorcraft. Nick West/Inspired Aviation

Inspired’s modular family could spin out into rotorcraft. Nick West/Inspired Aviation

It will also involve collaborative design with research organisations, universities, industry and non-traditional aerospace suppliers. What size of model to launch the family with is still under internal discussion.

The baseline aircraft would not immediately include electric or hydrogen propulsion, but would be designed to be future-proofed in a modular way so that new net zero technologies could be added as options. The modular design also means that certain modules or parts of the design (for example, the fuselage), might also be pulled through to eVTOLs, drones or even rotorcraft.

The requirements include simplicity, safety, 130kt cruising speed, night/ IMC capable, 20min sortie turnaround, as well as leveraging next-generation technology, such as electronic conspicuity, situational awareness and autonomous capabilities.

To fund this vision, Inspired itself is embracing innovation through its status as a Community Interest Company (CIC). That means it can accept donations, seek commercial lending and apply for local and government grants – as well as build aircraft under a fractional ownership model.

Summary

Make no mistake, this is a highly ambitious and visionary plan that Inspired Aviation is proposing – but one that could potentially stimulate a grassroots UK revolution in innovation, democratise flight and help solve a looming global pilot and engineer shortage. Moreover, success stories from outside the UK, such as Cirrus, Bristell, Elixir, Aura and Pipstrel shows that it can be done with the right determination, entrepreneurial spirit and vision. For the naysayers, West says: “Things are difficult in aviation. In fact, pretty much everything in aviation is difficult. It’s all about the human endeavour, innovation, the pioneering spirit and accepting the fact that we have to do something different if we want the industry in the UK to thrive”.

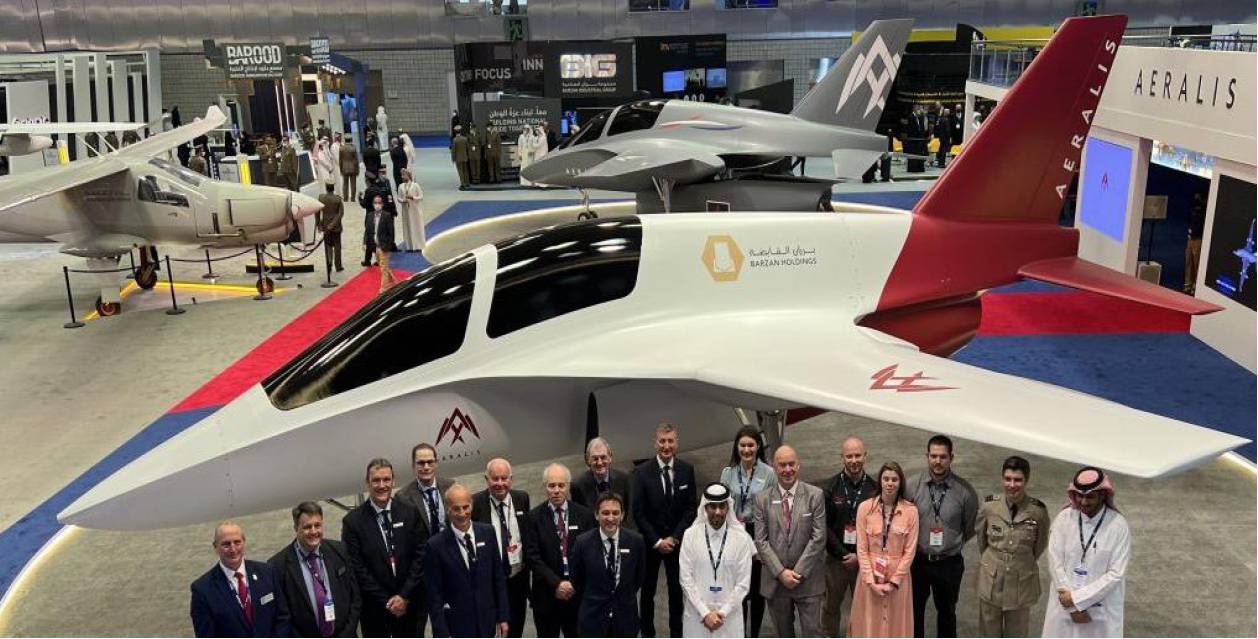

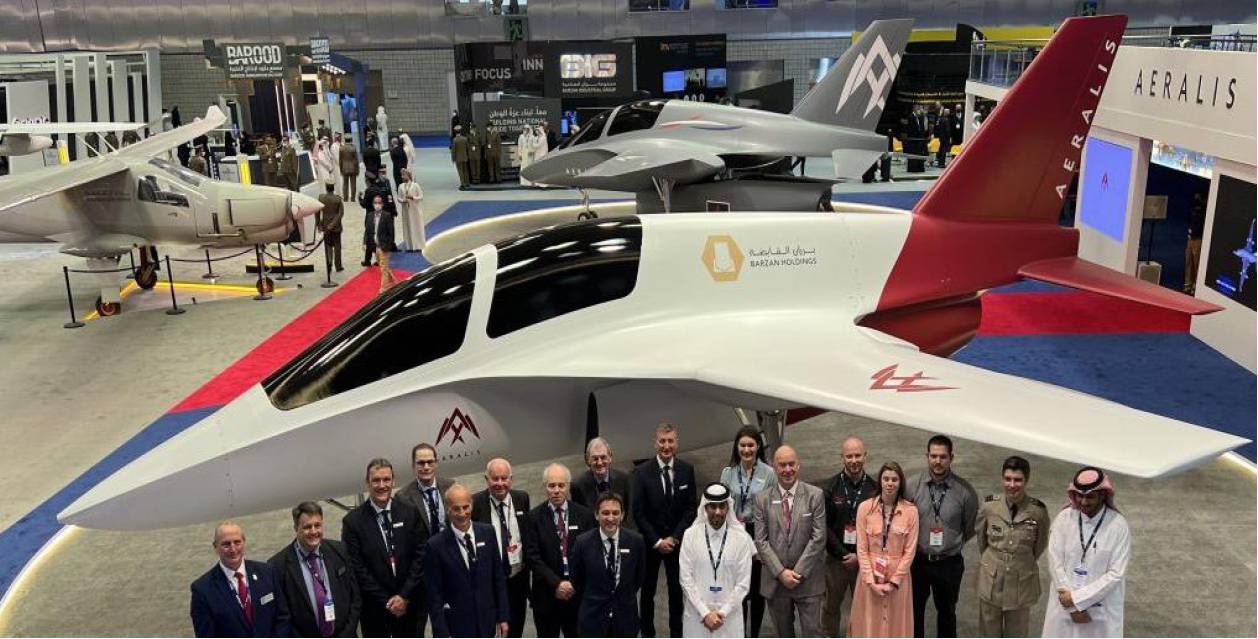

Another UK start-up aiming to disrupt the existing aerospace industry is Aeralis, with its modular trainer design. Does its approach of a modular airframe that can be adapted into a basic trainer, advanced trainer, lead in fighter and UCAV, hold a clue to Inspired’s approach? Aeralis

Another UK start-up aiming to disrupt the existing aerospace industry is Aeralis, with its modular trainer design. Does its approach of a modular airframe that can be adapted into a basic trainer, advanced trainer, lead in fighter and UCAV, hold a clue to Inspired’s approach? Aeralis

The UK-designed Game Bird GB-1 aerobatic aircraft is now being manufactured in the US. GameBird Aviation

The UK-designed Game Bird GB-1 aerobatic aircraft is now being manufactured in the US. GameBird Aviation Inspired’s first aircraft will be a Sling TSi kitplane, which will be used to develop its model of a distributed light aircraft manufacturing network. Nick West/Inspired Aviation

Inspired’s first aircraft will be a Sling TSi kitplane, which will be used to develop its model of a distributed light aircraft manufacturing network. Nick West/Inspired Aviation