AEROSPACE Faradair BEHA

No more excuses

With climate change still the number one long-term challenge to aerospace, efforts to decarbonise aviation are accelerating. The UK’s Faradair is now poised to make electrically-driven, 18-seat point-to-point commercial service a reality. PAUL EDEN reports.

Faradair has designed the BEHA for ease of operation at smaller regional airports. It will seat 18 passengers in regular service. Faradair

Faradair has designed the BEHA for ease of operation at smaller regional airports. It will seat 18 passengers in regular service. Faradair

In December 2019, Harbour Air debuted its six-passenger eBeaver, a magniX-equipped, electrically-powered conversion of the vintage de Havilland Canada DHC-2; the airline and magniX are now working together to certify the aircraft. The effort is pioneering since it involves a modified aircraft and follows the first-ever certification on all-electric, heavier-than-air, crewed production aircraft in 2020.

The Pipistrel Velis Electro received EASA certification on 10 June 2020. A small two-seater, based on the Slovenian manufacturer’s earlier Virus design, the Velis Electro flies for around 50 minutes on the power of two batteries driving a 76hp motor. Like the eBeaver, the Velis Electro demonstrates the practicality of electrically-powered aircraft but also encapsulates their limitations – payload and endurance are limited, suiting these aircraft for very particular missions.

Neil Cloughley, CEO and founder, Faradair (Faradair)

Neil Cloughley, CEO and founder, Faradair (Faradair)

Meanwhile, we are in an era where the urgent requirement for sustainable aviation is driving manufacturers to release imaginative and often unlikely concepts for electrically-powered aircraft. Some have flown re-engined demonstrators but proving that an old-technology airframe will fly on an electric motor is very different to proving a new, optimised aircraft design. The issue remains that the power density offered by batteries falls far short of hydrocarbon fuel, while battery weight – which is the same at the end of a flight as it was at the beginning – seriously compromises aircraft performance. Technology will inevitably catch up but the industry, media and public must accept that the development timeline from lightweight demonstrator to electric transatlantic airliner is one of decades.

Meanwhile, local and regional air transport offers a realistic proving ground for sustainable propulsion. An all-electric commuterliner carrying passengers in double figures is still some way off but a larger hybrid machine, employing a conventional turbine to drive a generator producing electricity for propulsion and aircraft systems, is achievable within a few years.

Fill the tanks of a hybrid aircraft with sustainable alternative fuel (SAF) and its already smaller carbon footprint is massively reduced, account for residual carbon in a well run, competent offset scheme and net zero flight falls within reach. What is more, with no requirement for charging facilities or the handling of novel fuels, a hybrid can operate from any airfield where SAF or Jet-A is available.

Now consider a hybrid designed for economically viable operations over regional routes carrying fewer than 20 passengers per trip or a respectable load of cargo. Flying a few hundred miles at most, such an aircraft would not require a high cruising speed, opening the door to a short take-off (STOL) design compatible with more local airfields. Ensure its noise signature is as small as possible and those living close to airfields would welcome it too.

In a post-pandemic world, where visiting larger, busier airports to access regional connectivity is likely to be less attractive than ever, customers will appreciate proper local options. That is especially true in the UK, where rail travel is generally inefficient, sometimes inconvenient and invariably expensive.

Remarkably, the process of creating an aircraft matching these requirements is already well advanced. From its headquarters at the Imperial War Museum Duxford, just off the M11 motorway, near Cambridge, UK, Faradair is busily defining its BioElectric Hybrid Aircraft (BEHA).

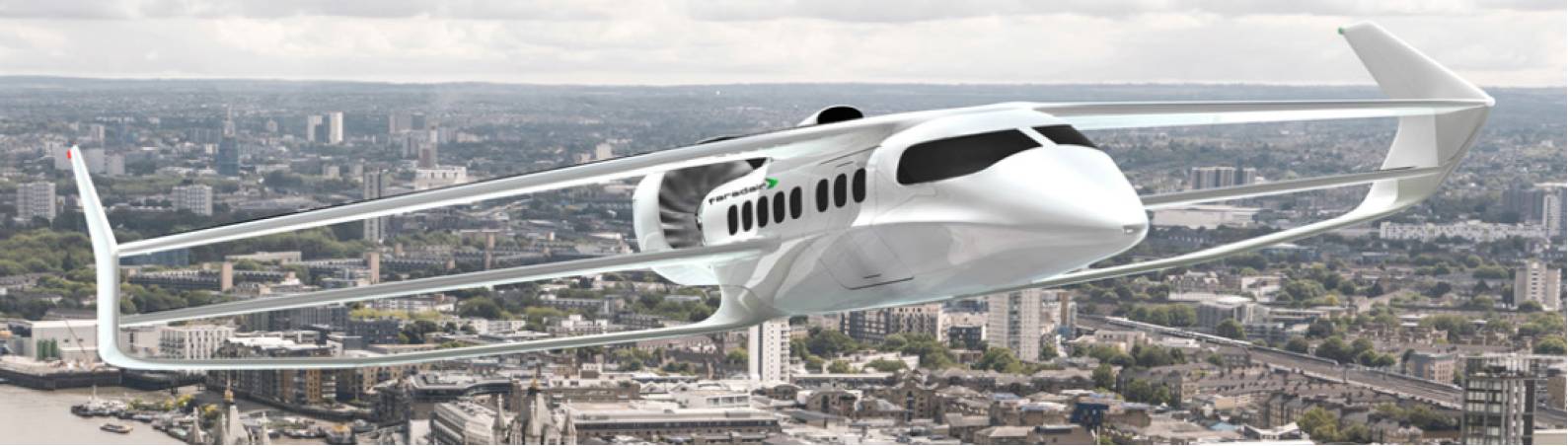

Optimised for regional operations, it features a so-called ‘triple box wing’, for exceptional STOL performance. Its design is yet to be frozen but, in essence, the BEHA is a triplane, the tips of its wings meeting on either side in an extensive endplate that does away with the requirement for fuselage-mounted vertical surfaces. Detractors suggesting that the centre wing’s spar will foul the cabin are misguided – the centre wing is effectively a lift generating bracing structure for the box design. The aircraft also employs a short undercarriage and large cabin doors, for easy loading and unloading of passengers and freight at airfields equipped with little more than a forklift.

All things considered, the fact that Faradair’s realistic, attainable and commercially attractive design has yet to attract any of the vast pot of funding released from government and industry sustainable aviation programmes is baffling. Yet the team continues under CEO and founder Neil Cloughley. In December 2020, Faradair confirmed its belief in BEHA with the announcement of several impressive partners, among them Cambridge Consultants, Honeywell, magniX and Nova Systems.

It also revealed plans for a unique operating model in which it would manufacture and operate 300 aircraft by 2030, in roles demonstrating the BEHA’s regional air transport, utility and special missions capabilities. Cloughley anticipates flying a prototype in 2024, with the first of the 300 becoming available around 2026.

“The aircraft will be suitable for a range of utility roles,” he says. Of the planned 300-aircraft fleet, 150 will be in a firefighting configuration, 75 completed as quick change passenger to cargo machines and 50 as freighters. The final 25 will be demonstrated in para-public roles, including logistics, border and fisheries patrol, and drug interdiction. Cloughley also notes: “The BEHA is sized to fit on the deck elevators aboard the Queen Elizabeth-class aircraft carriers,” and he envisages a missionised BEHA potentially flying ship-to-shore logistics and in other military roles.

Cloughley is determined to push ahead. On 28 April he announced that former Vice President Marketing for Boeing Commercial Airplanes, Randy Tinseth, had been appointed as the new head of Faradair’s Advisory Board, while noted former easyJet executive Tony Anderson was taking a board position.

Harbour Air first flew the eBeaver, with a magniX EPU replacing its Pratt & Whitney piston engine, in December 2019. magniX

Harbour Air first flew the eBeaver, with a magniX EPU replacing its Pratt & Whitney piston engine, in December 2019. magniX

Among the partners, Cambridge Consultants has local offices. Programme Director Gary Kemp says: “Faradair came to us for our experience in the development of electric vehicles and power electronics, and our long track record of developing mission-critical equipment. We manage projects around a thorough understanding of risk, retiring the biggest risks early, so confidence grows as investment is committed. Our use of a mature systems engineering process and quality system provides a high level of traceability. We often form strategic partnerships with other organisations to combine our strengths, and the Faradair consortium is a strong team.”

Duxford and its AvTech project, which aims to create an aerospace hub, is easily drivable from Kemp’s office. Faradair is the first major step towards making AvTech a reality and Kemp sees its potential beyond BEHA. “Cambridge has been a centre for innovation of world importance for at least 60 years and Faradair embodies this spirit of innovation in an industry where Great Britain has a long and prestigious history. The Cambridge Cluster has grown a critical mass of academia, high-tech industry, entrepreneurs and investors that supports high ambition; it may be that there is a particular opportunity to develop an industry in future-looking air transport that is a perfect fit for a centre of innovation like Cambridge.”

Cambridge Consultants has wide-ranging aerospace capability, including involvement in Iridium’s multi-billion-dollar NEXT satellite constellation. It is a far cry from a Cambridgeshire start-up, so what is the attraction of Faradair? “Our hope is that by being with them at the beginning we will form a long and mutually beneficial relationship as they grow. The mature partnership we have with Iridium is a great model for a vision of the future with Faradair. The main difference between the two is time and the main similarity is that they are both highly innovative and ambitious.”

Nova Systems, meanwhile, brings flight and certification test expertise to BEHA. Faradair is not unusual among start-up OEMs in lacking the trials capability of an established manufacturer. The path to certifying a new-generation aircraft is inevitably less well-trodden and likely to be strewn with as yet unimagined obstacles. A partner like Nova Systems, with deep experience and a proven track record of working with regulators is, therefore, essential to success. It is another example of Faradair’s realistic approach to creating a proper commercial aircraft.

Tim Butler, Head of Fixed Wing Europe at Nova Systems, explains: “We can plan a full test programme, from first flight to certification. We encourage people away from the idea that testing and certification happens only after design and engineering, because that’s a really expensive way of doing it. Instead, we advocate bringing us in early to write an integrated test, evaluation and certification plan. It’s important to look at what the programme is trying to achieve, the test and certification requirements and how to gather data during the development process so that it doesn’t all have to be gathered later. The aim is to accomplish as much as possible before beginning the flight test campaign.”

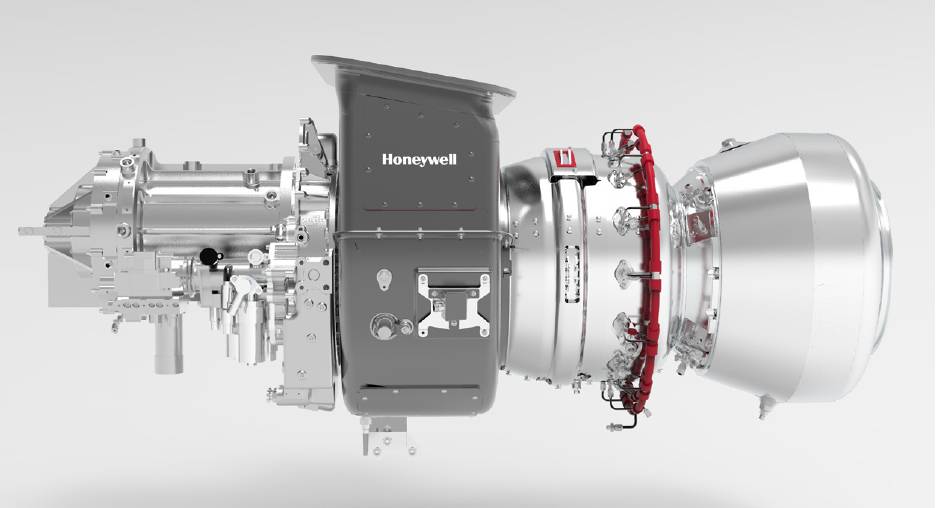

In March 2021, Honeywell Aerospace revealed that it was supplying a 1MW turbogenerator for the Faradair project. Based on the HGT1700 APU designed for the Airbus A350 XWB, it will power the BEHA’s electrical systems, including its ducted fan, flight deck, environmental control and battery charging.

Taylor Alberstadt, Senior Director, Honeywell Aerospace (Honeywell)

Taylor Alberstadt, Senior Director, Honeywell Aerospace (Honeywell)

Taylor Alberstadt, Senior Director, Business Development Electric & Hybrid Electric Propulsion at Honeywell Aerospace, describes the technology: “The term ‘turbogenerator’ designates the combination of a turbine engine and electrical generator(s), typically coupled by a gearbox and used for the primary purpose of producing electrical power.” BEHA has been engineered for easy adaptation to all-electric power when the technology is ready but Alberstadt confirms that Honeywell is evaluating how 100% SAF, rather than the 50% blend currently certified, might alter engine operation, performance and certification requirements. There could yet be hope for near carbon-zero hybrid flight without offset.

The 1MW turbogenerator has been developed with BEHA in mind and Alberstadt says Honeywell expects to work very closely with Faradair as the aircraft evolves. Moreover, in keeping with Faradair’s own vision for demonstrating the hybrid concept through a 300-aircraft owned fleet, there is a sense that Honeywell sees an opportunity to showcase its turbogenerator technology and its scalability. Alberstadt notes that the company has the capability, engine and generator platforms to produce turbogenerators in size classes from 250kW to more than 2MW, for multiple applications.