Airbus Vahana eVTOL demonstrator at the Paris Air Show. Airbus

Airbus Vahana eVTOL demonstrator at the Paris Air Show. Airbus

Fifty years ago when Airbus started, the company was run on paper. From now on a ‘datalake’ will inform everything and Airbus has 200 part-time and full-time staff whose job is ensuring data quality and supply to other parts of the business. Computer-aided design and aerodynamic models; virtual cabins for customers to walk through; cabin equipment with Internet of things sensors for more accurate take-off weight calculations; suppliers providing data about their products; Airbus’ manufacturing facilities generating data about its performance; flight test data, and information from airlines about their daily activities and experiences flying Airbus models. This was the connected industry, from concept to final touchdown, that Airbus presented at its Innovation Days 2019 conference in Toulouse, France from 21-22 May.

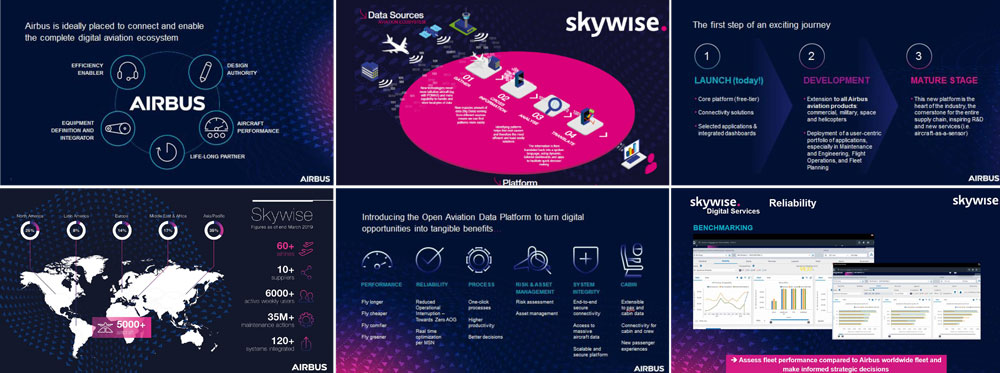

Airbus’ Head of Services, Remi Maillard, may have expressed it best when he said: “At Airbus, we produce aircraft and services with a total life cycle approach including dismantling of aircraft in a green way.” Maillard has a goal of achieving $10bn in service revenues over the next decade, and the services are enabled by the data. For these services, it is the Skywise platform that is the point of access for airlines, lessors, maintenance repair organisations, suppliers and regulators within the data eco-system Airbus is developing. Airbus has created a worldwide infrastructure with telecoms partners for the collation of data from its customers that it says is secure and reliable for Skywise.

Skywise is the platform through which Airbus says that it: ‘supports its customers’ activity on every aircraft-related aspect of the industry’. Today, this digital platform has more than 70 airlines and 6,000 aircraft, along with Airbus users. Airbus uses Skywise for its factory’s quality management, for example. Every month there are 10,000 users of Skywise, the European prime says. Two years ago, Skywise had four early adopter airlines with more than 20 internal Airbus applications.

“Skywise is like an aerospace app store. Airlines, or we, are developing, with Airbus services, apps, to resolve specific problems. It’s an open platform for airlines,” explains Airbus’ Head of Digital Transformation office, Marc Fontaine. The US carrier Allegiant Air told Airbus that Skywise stops one aircraft-on-ground event every day, Maillard adds.

In this connected future Airbus wants Skywise and the other platforms to be interoperable, a single flow of high-quality data and common tools, where possible. Head of Digital Design, Manufacturing and Services, Alan Tropis, spoke of tools that are expected to be the data backbone. “We are going to decide what tools are the backbone and what is the single flow of data.”

Fontaine explains that hoovering up all the data must be a company-wide capability if an enterprise is to gain a long-term benefit from the exploitation of its digital assets. Years ago, he adds, Airbus had a, ‘handful’ of staff dealing with data governance but now Airbus has 20 full time data guardians and another 180 who have that as part of their role. He spoke of, ‘digital continuity,’ which is Airbus’ concept of that data flow through the business, which will pave the way to digital twins of aircraft and factories.

As this digital ecosystem includes the supply chain, Fontaine recognises that there will have to be some help for the companies that supply it in this combrave new digital world. “We’ll need to take some industry wide initiatives to bring everyone with us,” he says. “A tier three or four (supplier) won’t have the resources to make the (digital) transformation.” He even sees a need to engage with industry associations, “we will have to play a role (there).” At the other end of the aviation information chain, Fontaine pointed out that passenger data was not going to be used. Data from the cabin was about the performance of the cabin equipment, not what passengers surf on the Internet.

This data chain, this digital continuity is a part of what Airbus refers to as Digital Design Manufacturing and Services (DDMS). Within this is are enterprise resource planning, product data management, the manufacturing execution system and the Skywise platform. These otherwise separate systems are combined for this digital continuity. For Airbus Chief Operating Officer, Michael Shoellhorn, this is essential for what is called, Industry 4.0, the connected factory. “Historically systems were monolithic and not connected to each other. Now they will be linked,” he explains.

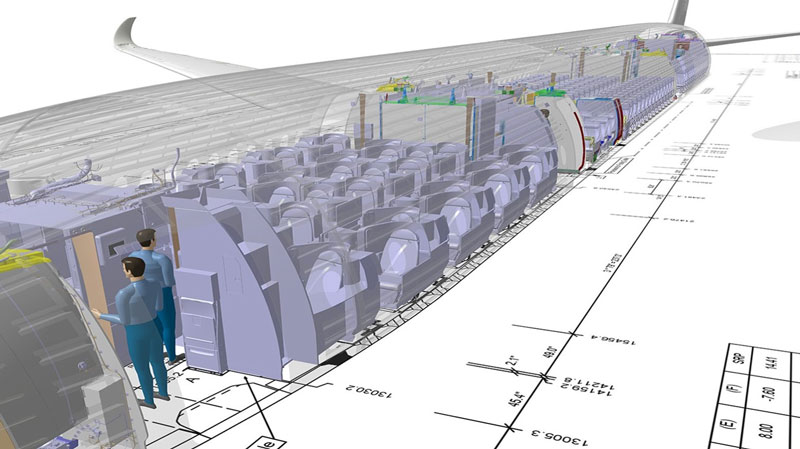

The DDMS is expected to help Airbus ramp up its production rates. The idea is to use that datalake, algorithms and artificial intelligence to, “really look at the data we have in our production system and how we use that data,” so mistakes are not repeated, says Shoellhorn. The idea is to co-design the product and production system simultaneously, with digital twins, based on that digital continuity, to achieve higher output from the very start of production. To make this step change Airbus is making digital models where the accuracy and detail is very high, Tropis explains.

An A350 virtual reality digital mock-up walkthrough. Airbus

An A350 virtual reality digital mock-up walkthrough. Airbus

Tropis describes what is possible with DDMS as moving aeronautics into, ‘mass production’. He referred to DDMS as a, ‘major transformation,’ and that its software platforms will be interoperable allowing a continuity of data, ‘so everyone knows when data changes’. The computer-aided design models Airbus has of its production line have so much detail, the Programmable Logic Controllers (PLC) which are used to control the machine tools, are also emulated. They can be programmed in the simulation to show the actual movement, allowing any possible physical clashes to be detected.

The digital twin of the production system will also show how automation can be applied sufficiently to help manufacturing, but not have a large shop floor footprint. Airbus wants to avoid costly automation and installations that make it harder to make the production line a flexible environment. The Internet of Things will have a role in this selective automation. Embedded in production equipment, it is envisaged as an aid, for example, for locating materials. In the past, staff walked too much to get the parts. With intelligent tracking and transparency, material delivery to the line can be more effective, Airbus says.

Within this data ecosystem driven world, staff have not been forgotten. Shoellhorn sees this datalake and DDMS as enabling an operator centric production system. “It has to help him or her and if it doesn’t, we have to rethink what we are doing,” he says. For that operator centric system, augmented reality with information overlaid over the lenses of smart glasses is expected to help with equipment installation, showing where cables and brackets need to go. Such is the technological change on the shop floor that, Shoellhorn says, Airbus is altering how it trains its apprentices. It is putting more emphasis on information technologies and robotics.

Beyond purely production engineering, Fontaine refers to data continuity projects when Daystalking about how this datalake is being applied to business challenges. He claims that, where Airbus has used this data analysis internally and where suppliers have employed it, they have seen two-digit performance improvements. “Things are changing really quickly in Airbus,” says Fontaine.

In the real world, the materials used in aircraft have seen a growing role for carbon fibre but, for the traditional metals, it is the manufacturing process that has been changing. While a lot has been written about additive manufacturing (AM), also known as 3D printing, Shoellhorn points out that AM is used for jigs and fixtures and there are few AM parts that actually fly. That could change. Airbus is investigating how to make AM parts more durable.

Airbus

Airbus

Airbus Chief Technology Officer, Grazia Vittadini, explains that a problem with 3D printed materials is the surface roughness. The vast majority of material failures begin with cracks at the surface. For this reason rough, uneven surfaces are more prone to cracking under the high loads and the cyclical loading associated with flight. Vittadini says that a solution could be surface treatments and Airbus is studying a plasma electrolytic polishing process to improve the fatigue properties of AM parts.

Another long-term project is quantum technology. Vittadini says that they are exploring quantum communications, sensing and computing. The computing is particularly important because of the huge processing needs for that datalake. “Quantum computing will enable us to process an unparalleled amount of data at unparalleled speed,” she says. Airbus Engineering Executive Vice-President, Jean-Brice Dumont, sees DDMS and quantum computing accelerating the design process.

Where the aerodynamicists and engineers try to find the best compromise between aerodynamics and the aircraft design, “with DDMS those (design iterations) loops are expected to be much faster. Eventually quantum computing will make it even shorter,” he says. In January, Vittadini launched the Airbus Quantum Computing Challenge to work with the quantum sciences community to tackle aerospace flight physics problems.

Flight physics will help with the very long-haul projects that Airbus has underway. Airbus’ Chief Commercial Officer, Christian Scherer, says that the: “A320 family provide single aisle prices with long range capability,” and he referred to Airbus’ A321XLR project and the aerospace giant’s A350 submission for Qantas’ Project Sunrise, which aims to have a non-stop Sydney to London flight. “When airlines have 18 to 19-hour flights, this is where you want the highest quality and avant-garde of your tech to be deployed,” he says. “We want to be the supplier with the A350 programme on it (Project Sunrise).” Scherer explains that Airbus has, “developed solutions for Qantas.”

Another aircraft that Airbus is working on is for urban air mobility. Its all-electric vertical take-off and landing (eVTOL) prototypes are called Vahana, a tilt-wing, and CityAirbus, a quadcopter. The Vahana made its third full-transition flight in April and CityAirbus made its first, ‘hop,’ in May, says Airbus’ Head of Urban Air Mobility, Eduardo Dominguez-Puerta.

Rather like Skywise, urban air mobility involves an ecosystem with market players and software. “We are working with airports and public transport operators in Paris, New York and Riyad,” Dominguez-Puerta, says. He explains that there is a market for people who do not want a two-hour journey from the airport to the city centre. Instead, for a ten-minute journey between the two, Dominguez-Puerta foresees passengers paying about $180 for the convenience.

Announced at the Paris Air Show was this EcoPulse hybrid-electric demonstrator featuring Airbus, Daher and Safran. AirbusWith an estimated 60% of the world’s population expected to live in the mega-cities of the future, he imagines a lot of future custom. Dominguez-Puerta also refers to the 21 European cities that have signed up to a European Union smart cities programme that includes urban air mobility.

Announced at the Paris Air Show was this EcoPulse hybrid-electric demonstrator featuring Airbus, Daher and Safran. AirbusWith an estimated 60% of the world’s population expected to live in the mega-cities of the future, he imagines a lot of future custom. Dominguez-Puerta also refers to the 21 European cities that have signed up to a European Union smart cities programme that includes urban air mobility.

Airbus’ single-engine helicopter Voom service is giving the company experience in this sort of market. Voom has flown 12,000 passengers, mostly business people, over 18 months and the level of repeat custom is 35%. While airport services are the initial market, Dominguez-Puerta foresees urban air mobility becoming rural air mobility with eVTOL replacing the need for roads, which he points out cost millions in any currency over their many kilometres. Airbus’ two eVTOL demonstrators are both autonomous.

While robot pilot control is being investigated for the air taxi market, it is single human pilot operations that Airbus is looking into for airliners’ cruise phase. Artificial intelligence (AI) would help the single pilot. Airbus is also investigating how AI can understand air traffic control’s commands to reduce the pilot’s workload. While AI could help with aviation’s pilot shortage, there is also going to be a need for more highly proficient technical staff. Vittadini sees a need to reach out to women, and more specifically, girls, to engage them in the industry and help them make a career choice early in their life. She explains how she thinks engineering and aviation can be sold to seven-year old girls as a career choice and the pitch is that it has a, ‘positive social benefit.’

From algae sourced carbon fibre structures, fully electric air-taxis and regional aircraft, reduced waste with 3D printed parts, less physical testing with digital twins, there are a lot of stories to tell about the positive social benefit of reducing the resources it takes to fly, and that datalake is going to help – for much of the next 50 years.