GENERAL AVIATION Electric world speed record attempt

Leading the electric charge

Rolls-Royce is currently conducting test flights of a battery-powered electric racing aircraft with the aim of setting a new world speed record and also gaining insights into how electric technology could be used to power a new generation of commercial aircraft. BILL READ FRAeS reports from Boscombe Down.

Before the end of this year, Rolls-Royce plans to break the world speed record for an electric aircraft with the Spirit of Innovation battery-powered racing plane.

Before the end of this year, Rolls-Royce plans to break the world speed record for an electric aircraft with the Spirit of Innovation battery-powered racing plane.

The record-breaking attempt is part of Project ACCEL (accelerating electrification of flight) which aims not just to fly fast but also to gather data and research into the applications of battery technology for future electric aircraft projects.

The ACCEL flight test team is made up of around 20 people from Rolls-Royce (responsible for safety, engineering and flight operations), UK electric motor and controller manufacturer YASA (motors) and aviation start-up Electroflight (powertrain design, battery design, control and simulation). Rolls-Royce has invested £3m into the project, with a further £3m funded by the Aerospace Technology Institute, in partnership with the Department for Business, Energy & Industrial Strategy and Innovate UK.

Record

The objective of Project ACCEL is to set a new world speed record for electric-powered aircraft. According to the rules set out by the FIA (Federation Aeronautique Internationale – World Air Sports Federation), aircraft have to set the record over four passes of 3km legs with a 1km approach at an altitude of under 500m. Currently, this record stands at 213mph (337 km/h) which was set in 2017 by a customised Extra 330LE racing aircraft powered by an engine from Seimens eAircraft – a division of Seimens – a company which was independent at the time of the record but is now owned by Rolls-Royce.

Aircraft

The airframe selected for the record attempt is a Sharp Nemesis NXT, a US-designed carbon fibre sports class single-propeller kitplane.

THE SPIRIT OF INNOVATION HAS OVER 6,000 CELLS – THE MOST ENERGY-DENSE BATTERY PACK EVER ASSEMBLED FOR AN AIRCRAFT

Powered by a highly tuned Lycoming TIO-540-NXT Thunderbolt six-cylinder engine, the prototype of the NXT (an acronym for Neoteric eXperimental Technology) currently holds the internal combustion air record speed holder with a FAI 3km speed of 415mph (667.8km).

The kit for the airframe of the NXT was delivered to Electroflight at Gloucester Airport in May 2018. Two airframes were acquired, one for test flights and another for ground testing. The 400hp Lycoming engine has been replaced by three electric motors and the fuel tank by three battery packs.

Power of three

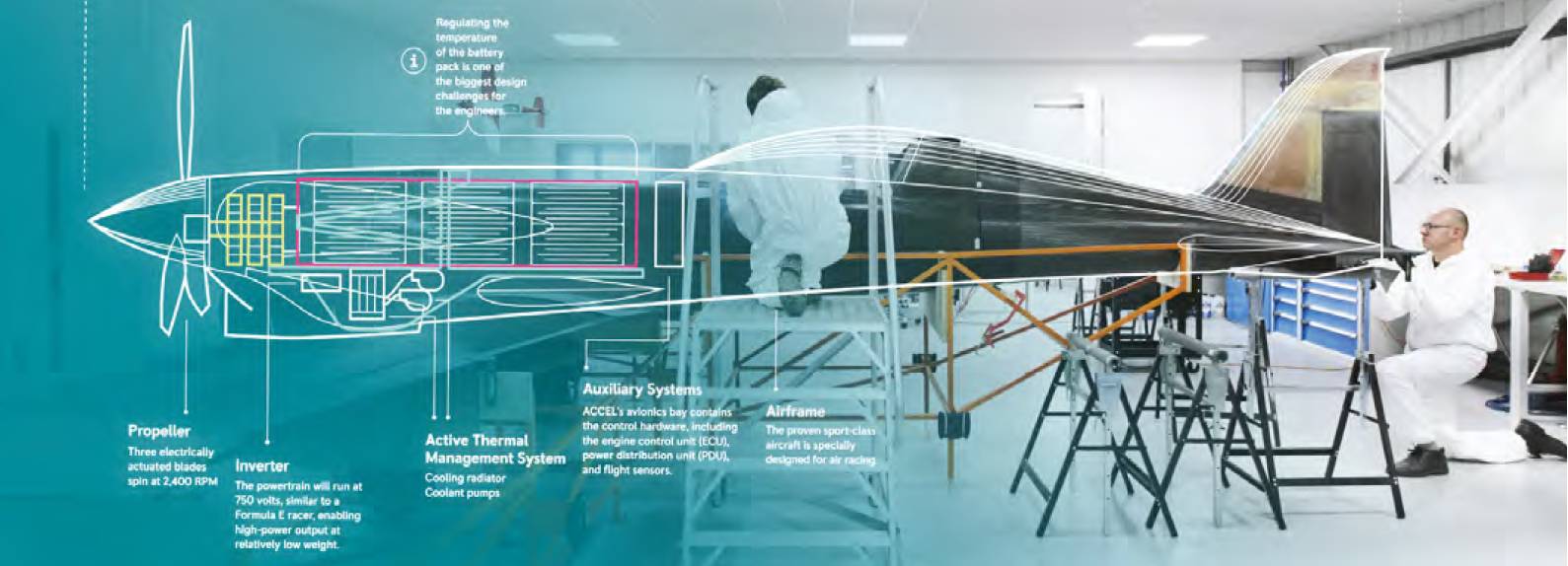

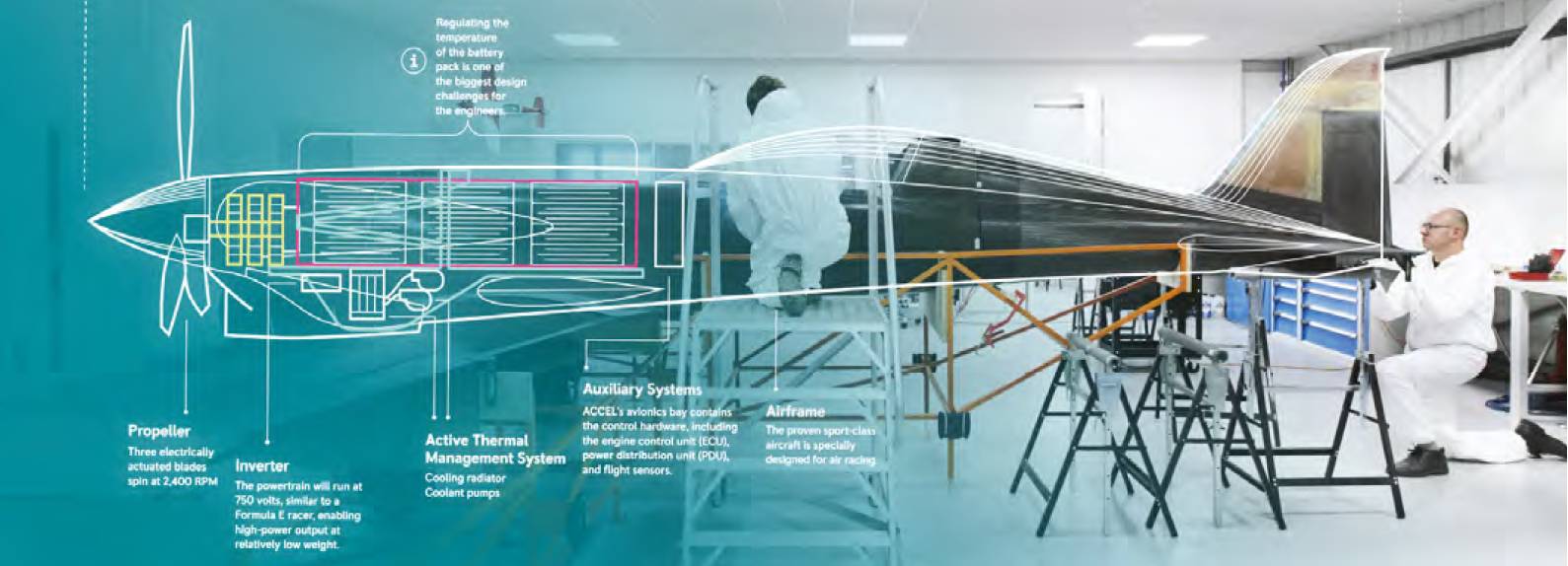

The 24ft (7.3m) wingspan aircraft is powered by three YASA 750v high power electric motors driving a single three-blade propeller via a single shaft running through all three motors. Rolls-Royce explained that the configuration of three motors powered by three battery packs was selected so that the aircraft can still fly safely if there is a problem with a motor.

Above left: The Spirit of Innovation is powered by over 6,000 battery cells. Above right: The batteries of the Spirit of Innovation (left) power the three electric motors.

Above left: The Spirit of Innovation is powered by over 6,000 battery cells. Above right: The batteries of the Spirit of Innovation (left) power the three electric motors.

Batteries packed

However, the main design challenge was that of the batteries which take up a large proportion of the aircraft. At an RAeS Flight Test Group online lecture in September, Rolls-Royce Flight Test Engineer, Andy Roberts described the technical challenges and lessons learnt from the integration of the Spirit of Innovation propulsion system, including weight, heat and power usage. “The main challenge of electrification is weight,” he explained, adding how the problem was how to pack sufficient power into a small space. The Spirit of Innovation has over 6,000 cells – the most energy-dense battery pack ever assembled for an aircraft. The batteries produce direct current (DC) which is converted through an inverter into alternating current (AC) for the motor.

To save weight, Rolls-Royce had designed a special containment system for the batteries which also acts as a structural part of the aircraft. While electric cars typically have an equal weight proportion of cells and packaging, the battery box in the ACCEL aircraft weighs 450kg, of which the cells account for 300kg.

Keeping cool

Another issue with using batteries to power aircraft is that of safety. “Batteries can get hot,” explained Roberts. “With the potential battery failure modes, you have to allow for the risk of batteries catching fire and a domino effect leading to thermal runaway and so the aircraft design has to include a tolerance to thermal events.” The case cells are separated by cooling plates and are in fireproof containers lined with Portuguese cork which provides a thermal barrier because it’s full of air pockets. There is also venting to take noxious fumes away, a purge system to maintain an inert atmosphere and an active thermal management system consisting of a coolant radiator and numerous coolant pumps.

The batteries and engines aboard the Spirit of Innovation are monitored by sensors which can record over 20,000 data points per second, measuring voltage, charge state and temperature for over 6,000 batteries, as well as the overall health of the powertrain. This data is used both to provide the pilot with in-flight information on energy usage and temperature warnings but also to gain insights into battery usage for future projects.

Avionics

In addition to the engines and the batteries, the aircraft design also incorporates a power distribution system connecting the battery to the engine, the aircraft control mechanisms and the avionics bay which includes the control hardware, engine control unit (ECU), power distribution unit (PDU) and flight sensors. Multiple low voltage power supplies provide redundancy for the control systems.

Speed vs distance

Because the aim of the ACCEL project is to fly at high speeds, the batteries will provide high power for a short period of time – the aircraft will only be flying for 7-8min with enough power remaining to land with reserves. However, if the batteries were discharged more slowly, the Spirit of Innovation should fly for significantly longer.

Many different systems have gone into the ACCEL electric racer. Rolls-Royce

Many different systems have gone into the ACCEL electric racer. Rolls-Royce

Ground tests – Ion bird

Before the Spirit of Innovation aircraft began flight testing, Rolls-Royce conducted an extensive series of ground tests conducted on a wingless static version of the aircraft, known as the ‘Ion Bird’ – taking its name both from ‘Iron Bird’ ground test aircraft and the li-ion batteries it operates on. Much of the ground testing was conducted under the restrictions of Covid-19 and was completed in September 2020. The 122 hours of ground tests, which included running the propeller at 2,400rpm and the University of Warwick testing the batteries to their point of failure, enabled Rolls-Royce to learn how to use the system and ensured that the battery was able to reach its maximum possible performance before being integrated onto the flight test aircraft.

Flight tests

This autumn Rolls-Royce began testing the flight test version of the ACCEL aircraft at the Ministry of Defence’s Boscombe Down airfield, currently managed by QinetiQ – a site with a long heritage of experimental flights. In his September lecture, Andy Roberts explained how Rolls-Royce, while usually just supporting customers conducting their own flight tests, does have its own flight test pilots. It also has a number of flight test aircraft, including a Boeing 747 engine testbed based in the US, as well as a1944 Mk XIX photo-reconnaissance Spitfire with 2,000hp Griffin engine which can go at over 400mph. Unlike some flight test programmes, Rolls-Royce has relied on using real aircraft rather than creating a simulator. As part of the preparation for Project ACCEL, Rolls-Royce test pilot Phill O’Dell flew a piston version of the NXT racer at 350mph in the US. The test pilots have also flown over the electric speed record course in the Rolls-Royce Spitfire which has very similar dynamics to the NXT.

Flown by Phill O’Dell, the Spirit of Innovation aircraft took to the air for the first time on 15 September with a 15 minute flight. The first flight achieved a speed of 210mph – very close to the current record of 212mph. A number of further test flights, the details of which have not been disclosed, followed shortly afterwards. Over the next month, subject to test results and flying conditions, Rolls-Royce plans to conduct between 20-30 flights of 15min duration, each one gradually increasing flying speeds while ensuring that the battery cooling and other systems are all working as they should do. The aim of the tests is not just to break the current speed record but to see how far it can be exceeded with speeds of over 300mph (483km/hr). As speeds increase, Rolls-Royce has said that it may have to use the Spitfire as the chase plane to keep up with the electric aircraft.

During the tests, performance data will also be gathered on the aircraft’s electrical power and propulsion system. One interesting preliminary result from the first test flights is that the temperature levels have been very good, due to the addition of the ram air effect in flight, which could not be simulated in the ground tests.

The electric experience

Rolls-Royce Chief Test Pilot Phill O’Dell explained that the Spirit of Innovation is not very different to fly than the existing aircraft he is familiar with. One issue is that controllers can become concerned if they see the propeller stop on the taxiway. Phill, who has had to lose 2kg of weight like a jockey to help reduce the overall weight of the aircraft, also described how it was quite difficult to see where he was going while lying back in the low-slung pilot’s seat and had to wear special shoes to help control the aircraft. However, once the aircraft was flying, he said that the throttle was one of the best he had being ‘very responsive and very linear’.

Future projects

Once the tests are completed – and hopefully the speed record won – the Spirit of Innovation will not be used for any further flights. The project has enabled Rolls-Royce to learn more about the characteristics of batteries over the longer term which are relevant to future electric aircraft projects which will focus on endurance rather than speed with the aim of maximising range.

Rolls-Royce is already involved with a number of electric propulsion projects, including parallel-hybrid electric systems for the Tecnam P2010 H3PS (high power high scalability hybrid powertrain) technology demonstrator due to fly in November. Airbus’ CityAirbus UAM demonstrator and Vertical Aerospace’s eVTOL. It is also working with Tecnam and Scandinavian regional airline Widerøe, to develop an all-electric passenger aircraft, the Tecnam P-Volt based on the airframe of the 11-seat twin propeller P-2012 Traveller, to enter revenue service in 2026.

Rolls-Royce plans to use the experience gained from the ACCEL project in the development of a complete electric propulsion system for electric vertical take-off and landing (eVTOL) ‘air-taxis’ and larger electric-powered commuter aircraft. The company is also working on green solutions to power larger aircraft, including hybrid-electric systems, further efficiencies in gas turbine engines and sustainable aviation fuels (SAFs).

From left to right: Rolls Royce Chief Test Pilot Phill O’Dell, Propeller close up, Ground tests were conducted using the ‘Ion Bird’ duplicate aircraft.

From left to right: Rolls Royce Chief Test Pilot Phill O’Dell, Propeller close up, Ground tests were conducted using the ‘Ion Bird’ duplicate aircraft.

Power, size and altitude

Batteries used to power an aircraft have to endure unique conditions not found on the ground. One problem already highlighted is the risk of the arcing due to the corona effect. The higher the voltage used, the greater the risk. Arcing is also more likely to occur at greater altitudes. The risk of arcing can be reduced by separation of the cables but this becomes more difficult, the smaller the airframe. Designers of future commercial electric-powered passenger aircraft will need to make decisions on what voltage to run their engines on. Larger airframes will make it easier to separate cables but will also need more power to operate. The higher the aircraft will fly, the increase in the risk of arcing. Designers may need to adopt a number of different voltages depending on aircraft size, power and altitude.

There is also the problem that electric aircraft also have to have more frequent full discharges which can affect battery life, as cells will degrade with use at a rate dependant on how they are used. Unlike cars, aircraft cannot slow down or stop if batteries are running low. According to a member of the ACCEL team, batteries can only be recharged from 500 to 1,500 cycles before they degrade too much to be of use to power aircraft.

This could be a problem for eVTOL operators which will need to use full power for vertical take-offs and landings and require frequent recharges which could wear out their batteries quite quickly.

Rolls-Royce has also gained useful insights from the ACCEL project into battery recharging and the new infrastructure which will be needed at airports operating electric aircraft.

Second battery life

The company is also looking at the issue of what to do with degraded batteries. Batteries which have reached the end of their useful life powering aircraft can be used in marine applications which do not need the same discharge capability and then again in land use. There is also the issue of end-of-life battery disposal and recycling, a challenge which the aerospace industry has not yet had to tackle but which is monitoring the lead being set by the automotive industry which is currently tackling this issue.

New business models

In addition to new technology, the ACCEL project is also changing the way that Rolls-Royce plans to do business in the future. Up until now, the company has specialised in the manufacture and aftermarket care of gas turbine engines for other operators but has not been involved in other areas of the aerospace business. However, this business model is beginning to change as the company moves from being purely a powerplant business to a technology business. In addition to manufacturing electric engines, RollsRoyce is investing £80m into developing its own energy storage capability and will be launching its own battery on the market in 2025. It is also getting more involved in fuels and is currently working with Shell on the development of SAFs.

We conclude with a quote from Matheu Parr, the project lead for ACCEL: “Rolls-Royce has been a pioneer over the past 100 years and now we want to be pioneers in the next 100 years.”

Before the end of this year, Rolls-Royce plans to break the world speed record for an electric aircraft with the Spirit of Innovation battery-powered racing plane.

Before the end of this year, Rolls-Royce plans to break the world speed record for an electric aircraft with the Spirit of Innovation battery-powered racing plane.