2Excel Aviation – charter

2Excel also operates as an airline and has its own AOC (Air Operators Certificate). Its ‘Broadsword’ charter division operates two VIP Boeing 737s based at London Stansted and three turboprop Beechcraft Super King Airs out of Doncaster Sheffield Airport. As well as being used for business and corporate travel, the charter division also flies specialist groups, such as orchestras and sports teams. The Charter Division also provide AOG (aircraft on ground) services for easyJet, Jet2 and GECAS where it uses a King Air to carry space parts and client crew for aircraft which need emergency repairs.

The Blades

Another activity of 2Excel is the Blades aerobatic team crewed by former Red Arrow and UK National Aerobatic pilots who perform in air displays and compete in international air racing. However, what makes the Blades unique is that they are also the world’s only aerobatic airline, offering formation aerobatic experiences for the general public (see the online AEROSPACE Insight article, Carving a bigger slice of the action – The Blades go global, from May 2019.

Above left: Brochure cover for Broadsword charter service featuring VIP 737. Above centre: Blades aerobatic team. Above right: HM Coastguard customised King Air and Navajo. All images from 2Excel

Above left: Brochure cover for Broadsword charter service featuring VIP 737. Above centre: Blades aerobatic team. Above right: HM Coastguard customised King Air and Navajo. All images from 2Excel

2Excel Aviation – capability development

Based at Doncaster Sheffield Airport, 2Excel Aviation’s Capability Development division specialises in the design, manufacture, installation and certification of customised equipment fitted to aircraft for specialist applications. Its services include design changes, ETSO (European Technical Standard Order) approvals, repairs, production of parts, assemblies and installation kits, small aircraft maintenance and component overhaul, bespoke mission systems installations, airborne testing and evaluation and specialist electronic warfare, night vision and support for project requirements capture and management.

“We specialise in doing difficult things well,” said Steve Riley, 2Excel Director of Capability Development. “The Capability Development teams take ideas from concept, through design and testing, to manufacturing, certification and evaluation. Because we have one of the broadest scopes of approval for design and certification in Europe, 2Excel Capability Development has total control over the various steps of the development which can all take place in a single location. We also offer flight test and evaluation capabilities, leveraging the expertise of our operational test and evaluation pilots engineers and aircrew.”

“We specialise in doing difficult things well,” said Steve Riley, 2Excel Director of Capability Development. “The Capability Development teams take ideas from concept, through design and testing, to manufacturing, certification and evaluation. Because we have one of the broadest scopes of approval for design and certification in Europe, 2Excel Capability Development has total control over the various steps of the development which can all take place in a single location. We also offer flight test and evaluation capabilities, leveraging the expertise of our operational test and evaluation pilots engineers and aircrew.”

Coastguard King Airs

One major project undertaken by Capability Development was the equipping of two King Air aerial surveillance, search and rescue platforms for the UK Coastguard. In March 2019, 2Excel’s Special Missions division won a five-year contract from the Maritime and Coastguard Agency to provide two customised Beechcraft King Airs for HM Coastguard to use on search and rescue, fisheries patrol and counter pollution missions.

Two Beechcraft King Air 200s were fitted with a multispectral surveillance suite. Some of the sensors were fitted in a belly pod which can be attached onto the aircraft. The first aircraft was rolled out in November 2019 – just eight months after the MCA awarded the contract. Originally the two aircraft shared a pod fitted with a Leonardo Seaspray 7300 radar but this year both aircraft are being upgraded to carry pods fitted with the more advanced Osprey 30 AESA radar.

Two Beechcraft King Air 200s were fitted with a multispectral surveillance suite. Some of the sensors were fitted in a belly pod which can be attached onto the aircraft. The first aircraft was rolled out in November 2019 – just eight months after the MCA awarded the contract. Originally the two aircraft shared a pod fitted with a Leonardo Seaspray 7300 radar but this year both aircraft are being upgraded to carry pods fitted with the more advanced Osprey 30 AESA radar.

“Our people make it happen,” added Arnie Palmer, Director of 2Excel Special Missions. “The development work on the King Airs drew on expertise across 2Excel, including our Capability Development team. This included integrated design, manufacturing and installation of the specialist mission equipment, as well as training our crews to operate the aeroplane.

“All the modification work on the King Airs was conducted in-house, added Matt Tones, 2Excel’s Head of Surveillance. “We did all the work on the aircraft here in Hangar 3 at Doncaster Sheffield Airport, including design, production, certification, and operation. When the Coastguard aircraft came in March we had no previous data to work on. By October we had made 25 design changes, something which would not have been possible if we’d had to work with third parties.”

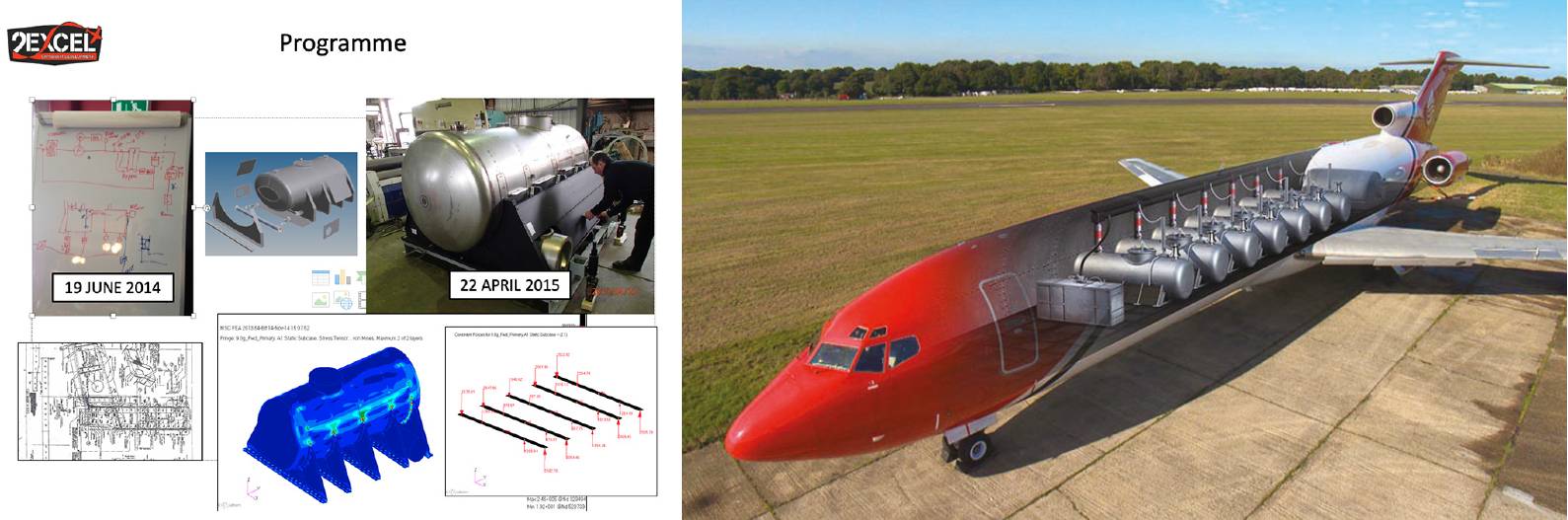

Above left: Development of the TERSUS dispersant system. Above right: The TERSUS tanks inside the 727 fuselage.

Above left: Development of the TERSUS dispersant system. Above right: The TERSUS tanks inside the 727 fuselage.

Oil spill dispersal 727s

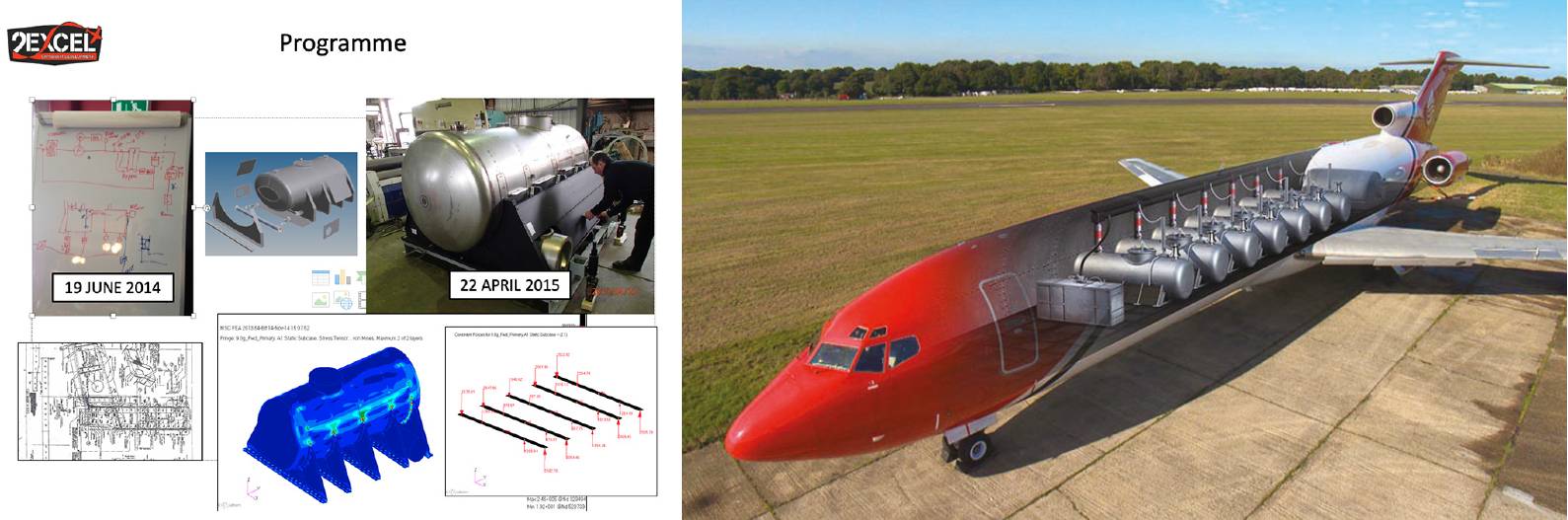

A second major project undertaken by the Capability Development division was the design and installation of specialised oil spill dispersal systems to two ex-FedEx Boeing 727 cargo aircraft for the industryfunded international co-operative Oil Spill Response Ltd (OSRL).

“We did everything ourselves, including design, manufacturing, system testing, certification, installation and flight testing,” explained Steve Riley. “We began in August 2014 with six people working for two months on the concept phase. We locked ourselves in a room and put our ideas down on a flip chart. Then we created a CAD image of what the tanks might look like. We then came up with a programme for design, manufacture and testing – at one point we had up to 44 people involved with the design and lots of interaction with EASA.”

A King Air fitted with conformal pod. All images from 2Excel

A King Air fitted with conformal pod. All images from 2Excel

OSRL oil spill response 727. Ian Black

OSRL oil spill response 727. Ian Black 2Excel Engineering’s extensive facilities at Lasham.

2Excel Engineering’s extensive facilities at Lasham.