SPACEFLIGHT European launcher development

Can Europe’s rockets close the reusability gap?

TEREZA PULTAROVA considers whether Europe’s space launch industry can give the behemoth that is SpaceX a run for its money.

Reaction Engines’ proposed SABRE powered spacecraft. Reaction Engines

Reaction Engines’ proposed SABRE powered spacecraft. Reaction Engines

When Wernher von Braun and other godfathers of spaceflight technology envisioned the future, they thought that, in a few decades, reusable spaceplanes would be criss-crossing orbits around the Earth, just like aircraft shuttle between continents. However, the development of technology stalled and throwaway rockets, initially brought in as a quick solution amid the space race between the West and the East, became the industry’s mainstay. British-based company Reaction Engines now hopes that its technology will one day challenge the status quo and turn the visions of early spaceflight pioneers into reality.

“When Kennedy committed to getting a man on the Moon, it was a bit of an anachronism because they were getting into space using vehicles based on ballistic missiles, which by their inherent characteristics are designed for a one-way mission,” says Richard Varvill, Reaction Engines’ Chief Designer and one of the company’s founders. “Rockets are not designed to carry people, they are not designed to be safe, they are not designed to be reusable.”

However, rockets worked and so, wary of the high stakes, the emerging space industry decided to stick with them. For example, Russia’s Soyuz rockets which, to this day, launch astronauts to the International Space Station, have barely changed since their first introduction in 1966.

However, rockets worked and so, wary of the high stakes, the emerging space industry decided to stick with them. For example, Russia’s Soyuz rockets which, to this day, launch astronauts to the International Space Station, have barely changed since their first introduction in 1966.

NASA experimented with reusability during the Space Shuttle era but that still needed an expendable rocket to get into space. It was not until the arrival of SpaceX, founded in 2002, that things started to move in a new direction. Varvill thinks that, despite SpaceX’s success with reusability and the ensuing cost reductions the company has been able to offer, a completely new technology is needed to truly usher in the spacefaring era envisioned by von Braun and his contemporaries.

“A normal expendable rocket has a 2-5% probability that it will not make it into space,” says Varvill. “When an astronaut takes a flight on a rocket, they really are rolling the dice. There is a one in twenty chance that they won’t make it. These are very bad odds compared with a flight on a civil jet, where your chance of dying is about one in ten million.”

For more than three decades now, Reaction Engines has been developing a new type of engine, called SABRE (Synergetic Air Breathing Rocket Engine), that will be able to switch between an air breathing airplane-like mode and a rocket mode that uses oxygen from an on-board tank when there is none outside to burn with the fuel.

SpaceX Demo-2 Falcon 9 and Crew Dragon stand ready at historic Kennedy Space Center Pad 39A. SpaceX

SpaceX Demo-2 Falcon 9 and Crew Dragon stand ready at historic Kennedy Space Center Pad 39A. SpaceX

The ability to breathe atmospheric air is key for SABRE’s game-changing nature. Conventional rocket engines burn fuel together with an oxidiser, which they carry with them in on-board tanks. The gear is heavy and, as a result, the rockets cannot lift into orbit that much cargo. Moreover, the rocket itself cannot be too complex and bulky, with back-up systems and safety features, which could, on the other hand, save the lives of the crew members in case of a failure. Similarly, features enabling repeated use, such as landing legs or wheels, add mass. The equation is simple – the heavier the rocket itself, the less space left for the payload and the higher the cost for the customer.

Reaction Engines envisions that SABRE would propel a high-tech spaceplane that would be, just like any modern aircraft, equipped with redundant systems for each critical piece of technology.

“The sort of vehicles that SABRE would propel would always have wings,” Varvill said. “They would look like aeroplanes. One of the advantages of that is that aeroplanes have abort modes, so if something goes wrong with the engines or one of the other subsystems, there will be a degree of redundancy in the vehicle and it would also have a propellant dumping capability. So, effectively, rather than just carrying on and hoping for the best, which is what you would generally do with rockets, you shut the failed system down, fly back to the airfield, dump the propellant and land as usual.”

Reaction Engines envisions the SABRE-powered spaceplane would, ultimately, take off from a regular runway and take its cargo or passengers all the way to orbit. The plane would return to Earth, landing at an airport, and be ready for a next flight within two days.

“To begin with, it might start as a two-stage solution,” Varvill said. “The spaceplane with SABRE engine would be on the first stage. It would take off the ground and then accelerate to a high Mach number. It would go out to the fringes of space and then release an upper stage that would take the payload on into orbit.”

Varvill says that flights on the SABRE-powered plane would not be quite as cheap as aircraft flights but certainly not as costly as rocket launches. “Effectively, with SABRE, we are trying to bridge that gap between rockets and aeroplanes and come up with a machine that has the operational characteristics of an aircraft.”

The engine could be reused several hundred times, Varvill added, a substantial improvement compared to the current first stages of SpaceX’s Falcon 9 rockets, which can fly about a dozen times. “That is [the envisioned SABRE performance] still terrible compared to aeroplanes, which can be used thousands of times,” said Varvill. “But, for SABRE, if we can get to a couple of hundred uses, that would be a fantastic achievement.”

The spaceplane, the company envisions, would be able to deliver 15t of stuff into low-Earth orbit, the region around the Earth up to the altitude of 1,000km.

Varvill admits that, to make the future envisioned by von Braun a reality, would require quite some years of hard work and a lot of money – in the range of billions of pounds.

The European Space Agency (ESA), as well as the UK government, support the development but there is not yet any debut flight in sight. In 2019, Reaction Engines successfully tested one of the key components of SABRE, the so-called pre-cooler, which cools and slows down the air drawn in during the supersonic air-breathing flight phase so that it does not melt the engine.

Daniel Neuenschwander, Director of Space Transportation at ESA, says that Reaction Engines has made great progress with its technology but questions remain around the potential vehicle that the engine would power. “SABRE is an ambitious project and there are technical challenges,” Neuenschwander said. “I am quite positively surprised by the technical milestones, which have been taken on the airbreathing engine. There are, however, still technical milestones ahead, especially at the vehicle level.”

In the past, ESA has been rather reluctant to embrace reusability. In 2014, the space agency’s member states decided to develop the non-reusable Ariane 6, a new heavy-lift rocket that will, in the next few years, replace the current European workhorse launcher Ariane 5. Richard Varvill, Chief Designer, Reaction Engines (Reaction Engines)

Richard Varvill, Chief Designer, Reaction Engines (Reaction Engines)

Following SpaceX’s success with reusable first stages of Falcon 9, some commentators and politicians criticised the conservative approach. Neuenschwander, however, cautions that, even today, it is not obvious whether reusable launchers, which are inherently more complex and therefore more expensive to build, make economic sense in the European context.

“In Europe, we don’t have the same volume [of launches] as a matter of fact,” Neuenschwander said. “SpaceX, for example, is highly supported by US national missions in terms of volumes and prices and it is a known fact that the prices paid by the US government are far beyond what European governments pay.”

The steady supply of well-paid government contracts, Neuenschwander suggests, enables SpaceX to offer cost reductions in the commercial part of its business that are beyond what is driven by reusability itself. “In Europe, we have an incremental approach to reusability, checking first above all the economic balance,” Neuenschwander said. “We are working on some reusability topics. But above that stands the economic equation, which we need to solve.”

Artist’s view of the configuration of Ariane 6 using two boosters (A62) on the ELA-4 launch pad, together with its mobile gantry. ESA/D. Ducros

Artist’s view of the configuration of Ariane 6 using two boosters (A62) on the ELA-4 launch pad, together with its mobile gantry. ESA/D. Ducros

ESA is currently pursuing several reusability demonstration projects which, Neuenschwander said, will help the agency and the European space industry ‘gain experience and knowledge’.

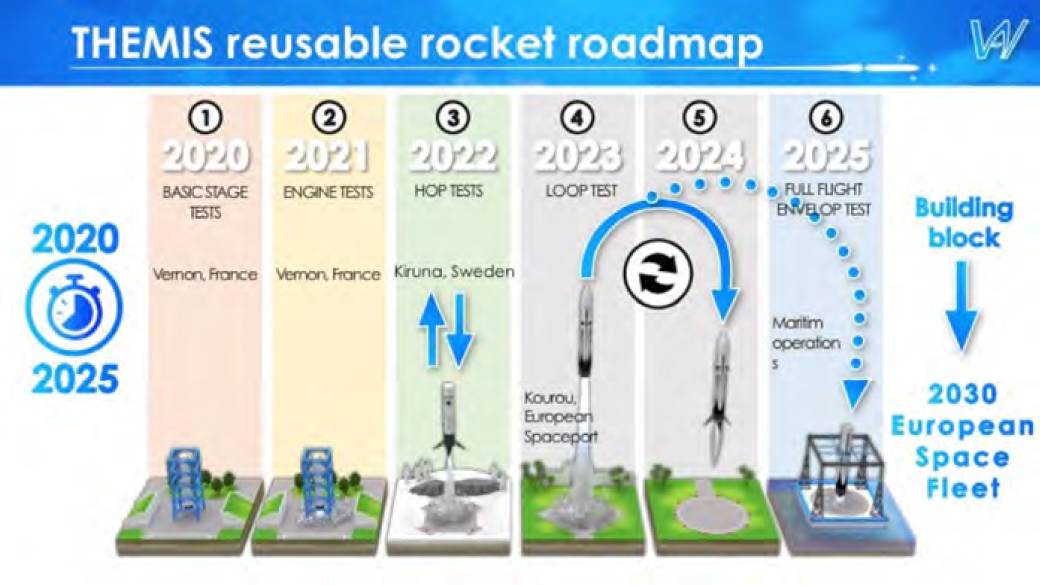

In December last year, ESA signed a €33m contract with European rocket maker Ariane Group to develop a reusable rocket stage prototype called Themis. According to Neuenschwander, Themis should be ready for hop tests (short vertical flights and subsequent landings on the launch pad) in 2022. It could perform its first sub-orbital flight in 2023 from the European spaceport in Kourou, French Guiana. It is, however, not clear whether Themis will ever become a part of a future operational rocket.