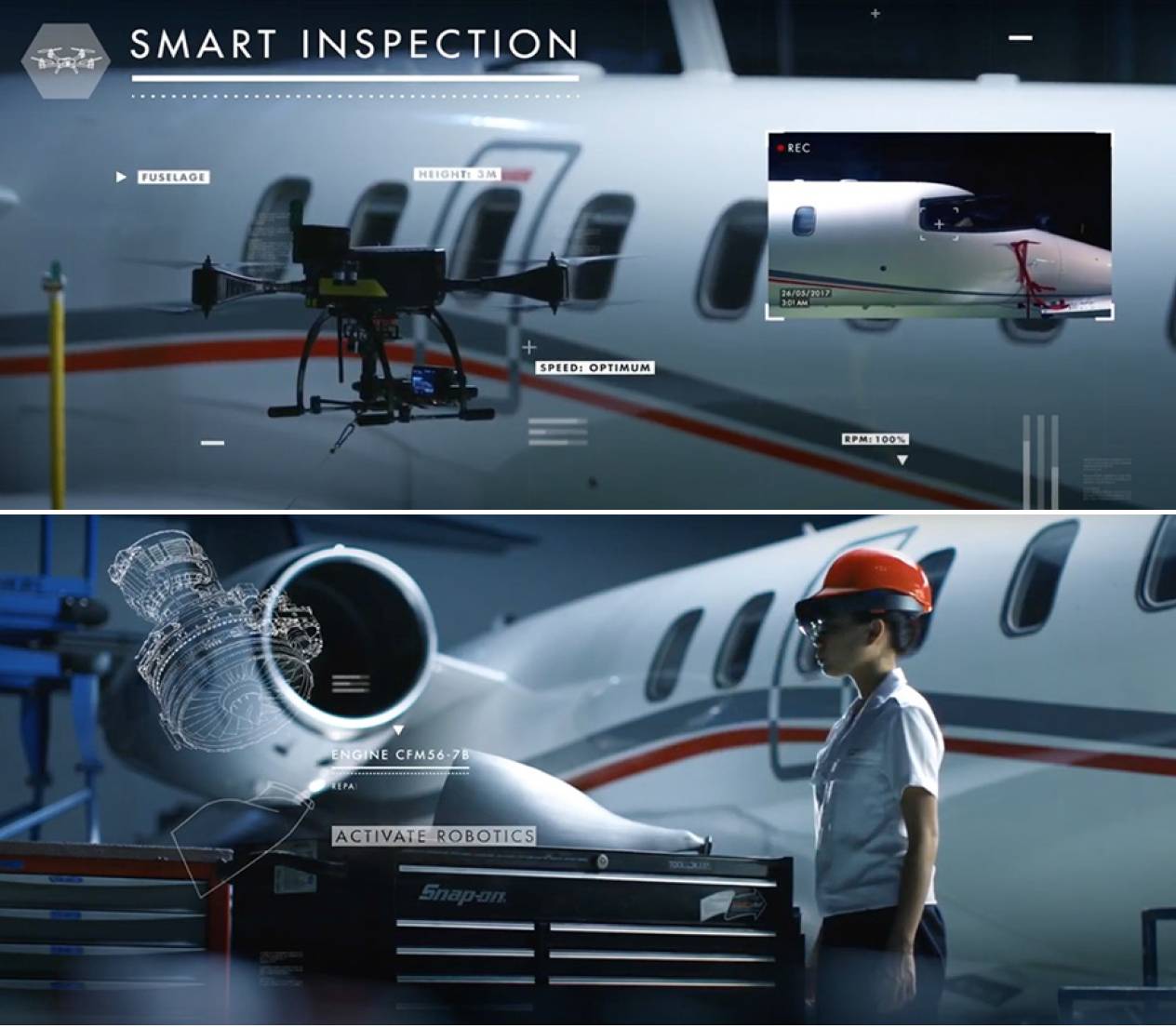

Through the use of smart goggles, STE engineers can conduct complex tasks, such as identifying a fault with a seat and ordering a new part to be 3D printed and sent to the hangar. STE/YouTube

Through the use of smart goggles, STE engineers can conduct complex tasks, such as identifying a fault with a seat and ordering a new part to be 3D printed and sent to the hangar. STE/YouTube

On 10 February, during the 2020 Singapore Air Show, the Singapore aerospace association A*STAR, hosted the Singapore Aerospace Technology Leadership Forum (SATLF). Introducing the event, the CEO of A*STAR Frederick Chew explained how this year’s conference was moving its focus from purely academic topics to industry-based topics, in particular to look at two areas of emerging technology – the increased use of artificial intelligence (AI) and digitalisation in the aerospace industry and also how new technology and aircraft designs could tackle the challenge of climate change. Part 1 of this two-part conference report looks at the issue of AI and digitalisation.

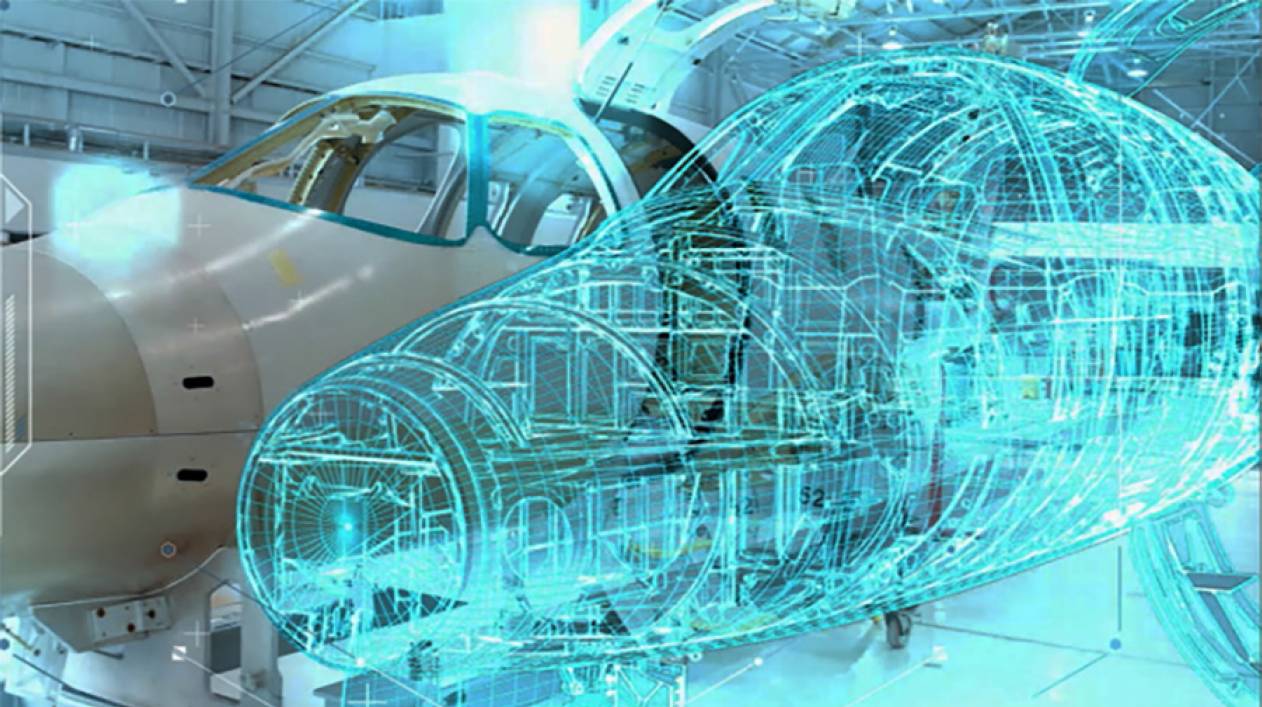

Electronic design at Dassault. Dassault

Electronic design at Dassault. Dassault

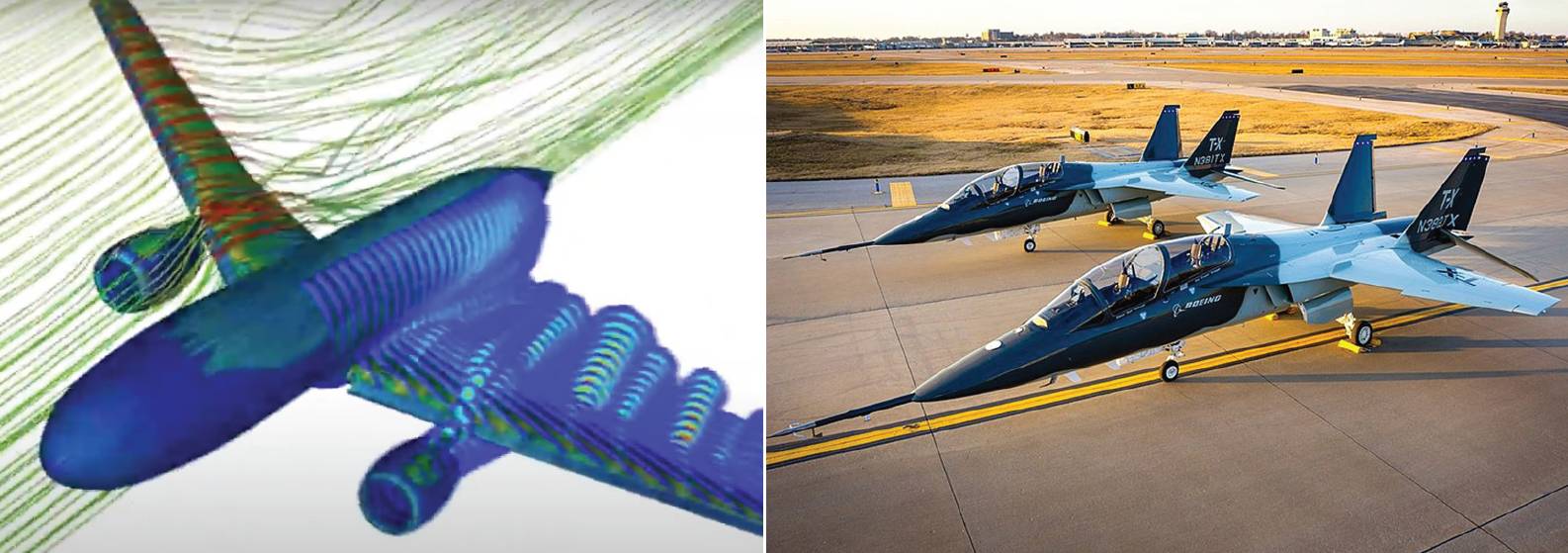

“We live in time of exponential change,” said Naveed Hussain, VP/GM of Boeing Research and Technology. He explained how digital data was being used at all stages across the aerospace sector, starting from design and analytics, through manufacturing, quality, assembly, delivery, in-service, modifications and finally, in recycling and reuse. Digital data is now being used in conjunction with physical systems not only as a record of what has been done but also in digital modelling of physical designs before they are created which simulate how they will perform. Digital systems are also used during an aircraft’s life to create a ‘digital twin’ of the physical aircraft which can be used to gain intelligence and insights in data analytics and digital maintenance. “To progress between needs and solutions, we need both physical systems and digital system models,” he explained. He added how Boeing’s new T-X military trainer (designed in partnership with Saab) was created in a model-based environment enabled by a ‘digital thread’.

However, there was still a lot of work to be done to make the data usable. “We’re sitting on a lot of data but it is not standardised,” Hussain said. “Currently the data is not connected – it’s varied, siloed and underutilised. The digital thread is only as strong as its weakest link.”

Digital systems are being used in a wide variety of applications across the aerospace industry. The conference heard from Benjamin Russell, Materials Science Expert at composites manufacturer Hexel, who explained how digital systems are being used to tackle some of the barriers preventing the wider use of such materials. In recent years, aerospace manufacturers have been making increasing use of composites to create complex aerostructures.

Russell told delegates how integrated computational materials engineering (ICME) is enabling the virtual testing of composites to predict how different manufacturing processes will affect the properties of final designs and how they will react under different environments.

Using a combination of computational fluid dynamics, processing and thermomechanical models, finite element analysis and material models, ICME can be used to model the effects of different elements in the designs. The particular objectives of virtual modelling are to better simulate and predict the properties of uncured resin, resin during cure, composite transformation, dimensional stability and laminate performance, in addition to predicting the effects of different ply sequences and simulating manufacturing.

Using ICME can greatly accelerate materials testing. “Previously it used to need 50 mechanical tests but it now takes seconds instead of months,” said Russell. However, ICME is only as good as the information that is put into it and there are still challenges to be overcome relating to the accurate modelling of composite materials, interfaces and interactions. ICME modelling of composite materials also requires large amounts of data which costs money to collect and process.

ICME also has applications in the creation of ‘digital twins’ in which a physical aircraft has a virtual digital counterpart which can be used to record changes made to the aircraft during its lifetime, as well as predicting future problems and modelling the effects of alterations before they are made. Using digital twins can also speed up aircraft testing and certification.

However, Russell cautioned that achieving the maximum potential of ICME/digital twins will require substantial collaboration from multiple parties. “There will need to be an effective and secure means to data sharing, standardisation approach and collaborative platforms to help unlock future opportunities.”

Many new aircraft are now created with a virtual digital twin counterpart. Siemens

Many new aircraft are now created with a virtual digital twin counterpart. Siemens

Another aerospace sector taking advantage of digital systems is maintenance, repair and overhaul (MRO). David So, SVP Transformation and Innovation in SIA Engineering, explained how his company is ‘building a digital workforce in MRO’. Part of Singapore Airways, SIA Engineering is involved in a wide range of different activities, including airframe maintenance and overhaul, line maintenance, component maintenance, fleet management, engine overhaul, cabin modifications, aircraft painting and training. So explained how recent years have seen technical advances in newer aircraft, and the phasing out of older aircraft and engines has resulted in less MRO work needing to be done and longer check intervals. There has also been increasing competition in the aftersales market from original equipment manufacturers (OEMs).

SIA Engineering makes extensive use of digital systems to link up all its different activities. This is enabled through the installation of advanced infrastructure, including wi-fi coverage, all-weather operations, combinable smart trucks and infrastructure-based scanners. The data is coordinated through a smart control centre which can record real-time information through digital job cards, enabling intelligent planning and tracking of resources, dashboard and visualisation tools. Automated dashboards enable the tracking of task and work completion status, material and tool management, tracking of manpower and equipment status/utilisation rate, as well as allowing data visualisation and analytics to gain new insights and make data-driven decisions.

Using mobile and augmented reality devices, SIA staff can access and input real-time information collected from a wide variety of data sources to better carry out their job functions. In addition to recording and disseminating data, the system can also automatically produce data-driven decisions, alerts and actions. It can also assist with aircraft health monitoring to predict faults and improve the allocation of resources.

Naveed Hussain from Boeing explains how robots were now being widely used for autonomous operations for precision assembly in aerospace manufacturing.

Naveed Hussain from Boeing explains how robots were now being widely used for autonomous operations for precision assembly in aerospace manufacturing.

The advance of digitalisation in the MRO sector was also highlighted by Lim Tau Fuie, CTO of ST Engineering Aerospace (STE) who described the company’s digitalisation journey over the past 20 years. “In MRO whatever you do, you have to report it,” he said. “With MRO workflow, traceability is key, so every job has to be documented.”

In 2000, STE began using a battery-powered, hand-held device called Aerobook to store information. This was upgraded in 2005 to the Aerobook 2.0 with more functions and then in 2015 to the Aerobook 3.0 which digitalised the complete end-to-end MRO process, including real-time monitoring of work orders, defects and approvals. Aerobook 3.0 is used as a support and management information systems tool by STE, suppliers and airline customers. STE is now working on a further upgrade called Aerobook 3.0+ which will include user interface enhancement, digital signatures and interactive manuals.

Lim Tau Fuie explained how STE employees use ‘wearable tech’ interactive goggles which used augmented reality, visual clues, voice interaction and virtual manuals, to facilitate engineering assistance and materials requests. Using Aerobook 3.0, they can order new parts which are taken by a forklift autonomous mobile robot (AMR) to smart cabinet automated storage and retrieval systems.

STE has also created AeroStream which is used in predictive maintenance, health monitoring and inventory optimisation. Fuie highlighted two examples of how data analytics in aircraft maintenance logs had been able to solve problems. The first was how the maintenance data could be used to forecast the parts and materials that might be needed in the future – thus avoiding over or under ordering for inventories by using the predicted quantities of materials. The second was how text analytics had identified discrepancies in standardised wording used for describing defects. This has enabled a solution to a particular problem involving a high incidence of defects, which was traced to the use of a particular cleaning agent in a fuel panel.

STE also makes full use of digital systems in its MRO work. STE/YouTube

STE also makes full use of digital systems in its MRO work. STE/YouTube

The conference speakers also consider the opportunities and challenges posed by the increased use of artificial intelligence (AI) in robotic systems. Naveed Hussain from Boeing said that AI was being increasingly used across the aerospace industry. Through advances in machine learning, robots were now being used for autonomous operations for precision assembly in manufacturing while drones were being utilised for autonomous inspection. He explained how AI could help to boost productivity in engineering processes that were repetitive or unsafe for human operators.

Digital systems can be used to order new MRO components which are located and collected by autonomous mobile robots and transported to hangars for maintenance engineers to use.

Naveed Hussain VP/GM, Boeing

In the MRO industry, SIA Engineering uses smart trucks to transport components, as well as collaborative drones and robots to assist in detecting defects in aircraft inspections. STE also uses robots in its facility, automating material movements and minimising tedious or hazardous tasks. Autonomous mobile forklifts are used to move materials around hangars, while robots are used for airframe sanding and floor grid drilling. Lim Tau Fuie told delegates how using robots minimised human exposure to hazards and harsh environments, such as heights and confined spaces.

STE also utilises robotic systems to inspect aircraft for defects. Previously, human inspectors had only identified some defects on aircraft but the AI systems had found far more. By using AI, STE were able to highlight a number of different defects – 6575% of which involved missing screws, paintwork irregularity and dents, 25-30% were scratches, stencil markings, nicks or surface corrosion and 3-5% were issues relating to antennaes, lightning damage, fluid leakage or cracks.

However, neither David So or Lim Tau Fuie thought that aircraft inspections should rely entirely on machines. “The MRO industry has still got a long way to go with AI inspections,” remarked So. “There are problems of accountability, so we use machines to augment manual inspections.” Fuie agreed: “We use AI to supplement visual inspections. We still need to convince the safety case for automatic systems.”

Above left: Digital twin technology is being used for virtual flight testing of new aircraft designs. Ansys YouTube

Above right: The Boeing T-X Military trainer was created in a model-based environment. Secretary of the Air Force Public Affairs

Above left: Digital twin technology is being used for virtual flight testing of new aircraft designs. Ansys YouTube

Above right: The Boeing T-X Military trainer was created in a model-based environment. Secretary of the Air Force Public Affairs

Herve Jarry, CTO & VP Technical from Thales Singapore, described how AI is one of several emerging mega trends influencing aerospace – the others being big data and automation, safety and security and the environment. There were big hopes for the future applications of AI, particularly in air transport. Pilotless drones are already in widespread use, some controlled by human operators and some autonomously. Proposals for eVTOL (electric vertical take-off and landing) air taxis are talking of using AI systems for autonomous flight. Pilots of commercial aircraft are already surrounded by multiple automatic systems to assist them to fly aircraft. By 2030, Jarry suggested, there could be single pilot operations for passenger aircraft and, by 2035, autonomous flights.

While it was agreed that AI and digital data could be of great benefit to make decisions and help with complex subjects, there is some debate among the speakers as to how far machines could be used to replace humans. “The purpose of AI is not to replace but to augment – at least not at the moment, said Naveed Hussain from Boeing. “The human-machine interaction is of high importance.” Herve Jarry from Thales added: “It’s not man vs machine, it’s man working with machine.”

Another challenge is the issue of data storage and accessibility. Data systems harvest information from multiple sources, generated from platforms owned or operated by multiple stakeholders. Who has ownership of this data and who should be allowed to see it? How secure is the data from being accessed or altered by third parties? For those who are authorised to use the data, what standards should it follow and what format should it be in?

“We all realise that there is value in data,” said Naveed Hussain. “Some is in intellectual property (IP), some in insights from data. There is lots of data coming from platforms which is owned by the operators – the airlines. We need to have partnership between operators and MRO providers which may also involve the OEM.”

One solution to the problem with digital data sharing was suggested by the Singapore Minister for Trade and Industry, Chan Chun Sing, in his keynote speech who proposed that Singapore could be developed as an ‘honest broker’, acting as a hub for data sharing for engines, aircraft and operations. “Singapore must be a safe harbour for technology and talent, open for partnership with all organisations and institutions to promote the free flow of data in a secure way,” he said. “We need to create an environment where intellectual property protection is paramount, to get rules and to keep upgrading them. If we do this well, we will distinguish ourselves from others.”

The first part of the conference was summarised by Naveed Hussain: “We’re at a new dawn for aerospace with many different systems now converging. It’s an extremely exciting time to be in.”