Pushing the Envelope

Pushing the envelope

Colour-changing liveries

Robert CoppingerAirliner colour schemes or liveries can vary greatly with designs ranging from animals to characters from films, but what if they could be designed to change at the flick of a switch? At the technology show, CES, held in the US earlier this year, BMW demonstrated its iX Flow car, a technology demonstrator whose exterior changes colour in seconds.

Robert CoppingerAirliner colour schemes or liveries can vary greatly with designs ranging from animals to characters from films, but what if they could be designed to change at the flick of a switch? At the technology show, CES, held in the US earlier this year, BMW demonstrated its iX Flow car, a technology demonstrator whose exterior changes colour in seconds.

The iX Flow is a BMW all-electric sports model with a laminated electrophoretic film tailored to its body contours. When electricity is applied, the electrophoretic film produces different colour pigments across the surface. The colour change is not sophisticated enough to show animations – the car’s skin simply changes from one colour to another but in a fluid manner across the entire vehicle’s body. The iX Flow’s range of colours is also quite limited, to black and white and shades in-between.

The electrophoretic film consists of millions of microcapsules, the diameter of a human hair, that contain differently charged white, black or coloured particles. Applying a current causes white, black or coloured pigments to collect at the surface of the microcapsule, giving the car body the desired colour.

This is the technology that makes e-reading devices possible but the words of Shakespeare are not going to be read across the exterior of an airliner or top-of-the-range automobile.

While the application of electrophoretic film to cars may appear clear, the operational environments in which cars and aircraft are tested are not so far apart, opening up other possibilities.

While airliners fly at 36,000ft where it can be about –55°C, the aerodynamic friction travelling at a typical cruise speed raises the aircraft’s surface temperature to approximately –25°C.

Cars are tested in environments as low as –40°C and both automobiles and aircraft are expected to operate in hot equatorial, desert-like conditions. Temperature is a major obstacle for the technology. The company that made the film, the E-Ink Corporation, said it is ‘not rated for aircraft or automotive use yet. Because it’s a concept and is not a commercial product, it will not go into production any time soon for the automotive industry. Additionally, E-Ink is not focused on the aviation industry at this time.’

However, there are aviation applications that call for low altitudes, along with a much more benign temperature range. Advertising blimps is one of the possibilities where a simple logo could change colour to catch people’s attention. The blimp concept is a feasible one for E-Ink co-inventor Jonathan D Albert. Now working at the University of Pennsylvania, Albert invented electronic ink with his colleague Barrett Comiskey.

Albert sees two additional challenges for airliners. The first is the compound curvature of the typical airline’s tube shape and the second is rain potentially at any altitude. However, he likes the blimp idea and agreed that electric vertical takeoff and landing (eVTOL) aircraft were another potential application. A medical evacuation eVTOL could use electronic ink for a flashing red plus sign. Electronic ink can produce a wide range of colours, Albert explained, but it requires different approaches to the technology.

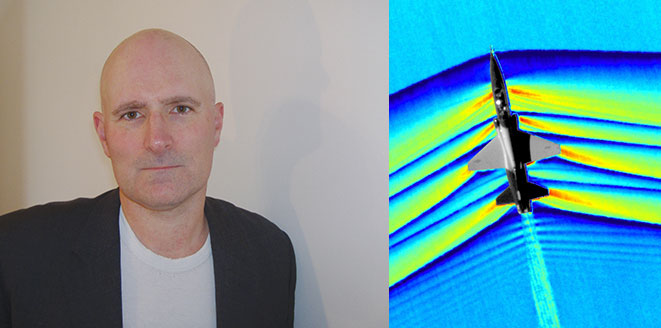

For a reliable near-term application, the colour scheme needs to be simple. Electric air taxis have the advantages of being small two-person aircraft with a ready source of electrical power and a small surface area without compound curves. In a crowded airspace, an eVTOL could darken its livery to be clearer against a bright sky or brighten its appearance at dusk or night, in addition to its on-board lights. Colour-changing technology also has potential military applications as the ability to blend with the background scenery for the military is a clear advantage. For now, however, the paint shops have nothing to worry about.